| Heaters The devices described here are probably not “free-energy” devices as such, but in spite of that, it is an area of considerable interest to many people, and the subject is included here because of that. If you do not live in an urban area, then a solid fuel stove can be an economic solution, especially if the fuel can be collected free from wooded areas. Stove design has advanced considerably and it is now possible to make a simple stove with very high efficiency and very low emissions as shown here:  Although this stove is a very simple construction, it’s efficiency is very high indeed. The best fuel is made of smaller pieces which rest on a simple shelf. Branches work better than large pieces of wood as the consumption is more complete. As the fuel is consumed, it is pushed further into the stove, which gives the user an appreciation of the rate of consumption. Having the fuel resting on a shelf has the major advantage of allowing air to flow both above it and below it, which gives improved combustion. The operation is said to be so good that there is virtually no residue and no emissions. Again, if land space is available, a solar oven (or Stirling motor) can be used, either to store energy for later use or generate heat for cooking or home heating, as can hot-water solar panels. However, it is only realistic to consider the application to be during the night in a built-up area with little or no spare space for equipment. Electrical heating, while very convenient, is usually expensive, and it often seems that the effectiveness of an electric heater is not directly related to its power consumption. In theory it definitely is, but in practice it just does not seem that way. There are other alternatives. One of the other documents in this set, shows how to construct a Stanley Meyer style electrolyser which uses ordinary tap water and splits it into burnable fuel using just a low power electrical input:  The difficulty in creating a heating system which uses the gas produced by this unit, is in the very high temperature produced when the gas is burnt. Stan overcame this problem with by designing a special burner which mixes air and burnt gasses in with the gas before it is burnt. That lowers the flame temperature to a level which is suitable for heating and cooking:  While this looks a bit complicated, it’s construction is really quite simple. The combination of the Meyer electrolyser and Meyer burner form a system which has the potential of being operated from a solar panel and battery as shown here:  A system like this needs extreme care as the hydrogen / oxygen (“hydroxy”) gas produced is explosive. So:

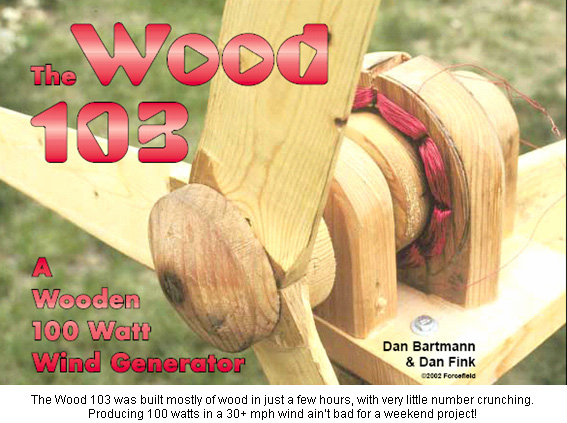

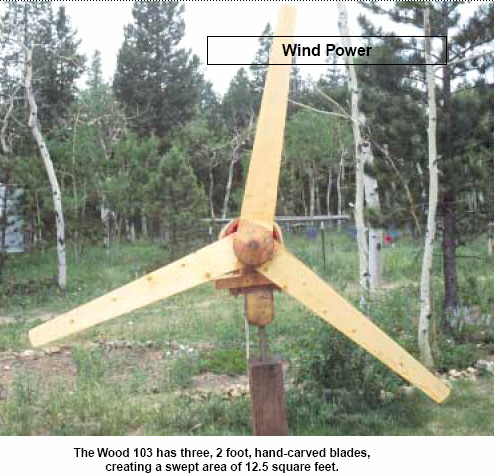

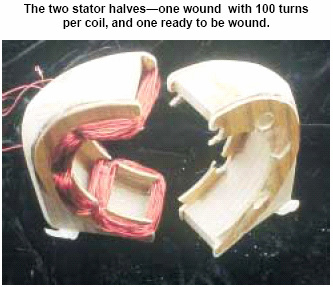

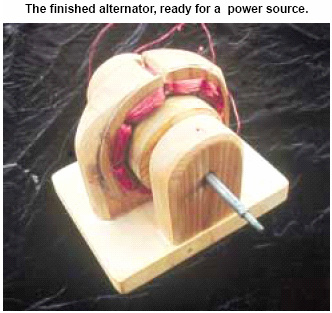

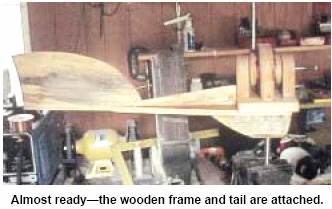

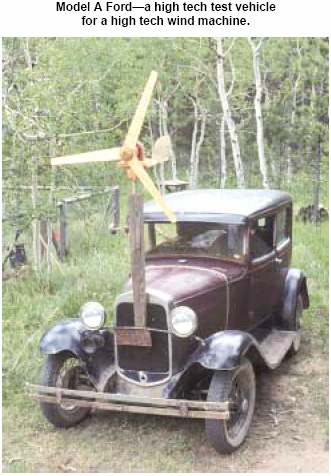

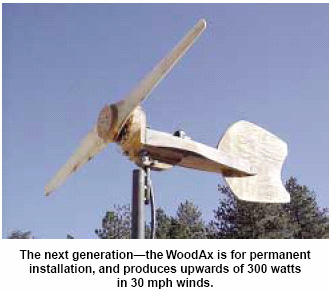

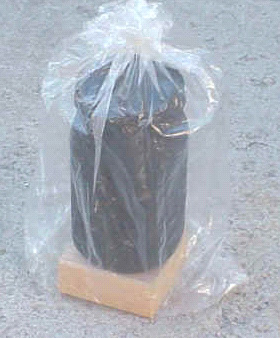

The idea is to bubble the hydroxy gas produced by electrolysis of water, through a liquid hydrocarbon such as turpentine. The bubbler should have a large number of small holes in the incoming tube, so that a very large number of small bubbles of hydroxy gas pass through the hydrocarbon. This brings the majority of the hydroxy gas into intimate contact with the hydrocarbon and the process is claimed to convert the hydroxy gas into a new variety of gas which is not explosive, can be stored for later use, and which burns with the same characteristics as coal-gas (“town gas”). At this point in time, I do not know of any recent tests to confirm this, so the claim should be treated with caution and careful tests carried out in the open, lighting the gas remotely and taking refuge behind a robust protective object. Having said that, in my opinion, it is likely that Henry Paine’s claim is correct, but that is only my opinion and I have not confirmed it with any form of practical test. Sang Nam Kim. Mr Kim of Korea also proposes methods of using hydroxy gas for heating and using Henry Paine's hydrocarbon bubbling method. He has four patents on the subject of heating: US 6,397,834 in June 2002 - Heating Furnace US 6,443,725 in September 2002 - Energy Generatin US 6,761,558 in July 2004 - Heating Apparatus US 7,014,740 in March 2006 - Electrolyser The first of these shows his method of getting both beneficial radiant heat and convention heating from a stone construction like this:  This unit is intended as a seriously powerful heating source for a minimum of one room. Mr Kim quotes a hydroxy gas requirement of 30 litres per minute which is a very considerable amount, and if the gas is produced by electrolysis of water at Faraday efficiency, it would need a current draw of 4.2 kilowatts. There is every indication that Mr Kim's method of electrolysis is low efficiency as his latest patent shows a radiator and fan:  Mr Kim also shows a burner intended for use with an existing furnace. He remarks that the outer casing gets to be red hot, running at 1,000oC or more, and so any replication of his design should be treated with care when mounting fixtures are being constructed. In this design, Mr Kim uses the Paine technique and recommends bubbling his hydroxy gas through hexane liquid (C6H14) where 0.3 litres of hexane per hour gets burnt as well as the hydroxy gas. He rates the hydroxy gas requirement of this burner as being 20 lpm, which at Faraday efficiencies, represents 2.8 kilowatts of electricity, although as mentioned before, it is likely that the actual amount of hydroxy gas in his 20 lpm volume is much lower than he thinks, and so will have a lower electrical requirement when using a more electrically efficient electrolyser. His burner is like this:  Mr Kim believes that the hexane prevents flashback ignition. He does not appear to specify the heating material inside the burner but it is probably stainless steel wool. He speaks of gas pressures of 1 Kg per sq. cm., which, if my calculations are correct is 14.22 psi. which is not possible for 100% hydroxy gas as it will explode spontaneously at 12 psi. due to its high energy state and electrical charge. He states that the secondary flames at the top of the unit "burn with a blue flame colour" and that is different to the flame colour lower down. Mr Kim believes that the hydroxy burnt at the bottom of the burner forms water vapour which is then split into hydroxy gas again by the very high temperature and that is the reason for the blue flames at the top. Personally, I don't believe that this will take place and that the effect may have a good deal to do with the hexane liquid being burnt. However, this burner design appears to be a good one for lower grades of hydroxy gas. If a higher grade of hydroxy gas is being used, please be aware that a hypodermic-size tiny burner orifice will be needed to avoid flashbacks and no commercial flashback arrester will work reliably with good quality hydroxy gas on every occasion and so a bubbler is absolutely essential. Electric power is very popular for heaters. However, with most appliances, it is a very expensive form of heating. There is a technique which is reputed to improve the efficiency and lower the cost of electric heating. This method involves rotating a cylinder inside an outer cylinder and filling part of the narrow space between the cylinders with some variety of light oil. This method has been patented more than once. In 1979, Eugene Frenette was granted patent 4,143,639 where a single motor is used to rotate the drum and power a fan to boost the motion of the hot air:  It is not immediately obvious why this arrangement should work well, but it appears that it does. As the inner drum spins around, the oil rises up between the two inner cylinders. It lubricates the bearing under the rotating drum and the rotation causes the oil to heat up. This heats the middle cylinder and air being drawn up around it by the action of the fan blade, is also heated before being pushed out of the top of the heater. After a few minutes, the outer housing becomes so hot that the thermostat attached to it, cuts off the electrical supply. The heater does not stop heating at this time as air continues to circulate through the heater by ordinary convection. In my opinion, it would be more effective if the fan motor were operated independently and did not cut off when the heater reaches its operating temperature. Very similar systems were patented by Eugene Perkins: January 1984 patent 4,424,797, November 1984 patent 4,483,277, March 1987 patent 4,651,681, October 1988 patent 4,779,575, and in January 1989 patent 4,798,176. His first patent shows a horizontal drum which is completely immersed in the liquid:  This calls for a much greater accuracy of construction in that the liquid has to be contained even though it has a rotating shaft running through the housing. This device pumps the heated liquid through central-heating piping and radiators. In his later patent of the same year, he shows a modified version with two drums and an impeller:  The “heat exchanger” is a radiator or set of radiators. He progressed to a system where the shaft rotation forces the liquid to be expelled through the tips of arms radiating out from the centre of the impeller hub:  Here, the liquid is forced into a small space between the rotor and its drum housing. This system has been used very successfully for water heating and some measurements indicate that it is at least 100% efficient and some people believe that it is well over the 100% efficiency, though they don’t want get drawn into long discussions on methods of measurement. It is sufficient to say here, that this method is very effective indeed. Frenette Variation: The Frenette heater design shown above with it’s two vertical cylinders, is not the easiest for the home constructor unless one of the cylinders (presumably the inner one) is constructed from steel sheet, as it is difficult to find two commercially available steel cylinders of just the right relative size to produce the wanted gap between them. A much easier variation replaces the inner cylinder with a stack of circular steel discs. As these can be cut from 20 gauge steel sheet fairly readily by the home constructor, or alternatively, cut by any local metalworking or fabrication company, any available size of outer cylinder can be used and the disc diameter chosen accordingly. The discs are mounted about 6 mm (1/4”) apart on a central steel rod which is rotated in order to drive the discs through the oil contained inside the body of the heater. While this looks like a Tesla Turbine, it is not because the spacing of the discs creates a different effect. The wider disc spacing creates shear as they spin through the surrounding oil, and this shearing creates a high degree of heating. It must be remembered that this is a heater, and the outer canister gets very hot during operation (which is the whole point of the exercise in the first place). For that reason, oil is used as a filling and not water, which boils at a much lower temperature. The larger the diameter of the canister and the greater the number of discs inside it, the greater the heat developed. To ensure that the discs do not come loose during prolonged operation, a hole can be drilled through them just outside the area covered by the locking/spacing nuts, and a stiff wire run through the holes and the ends either welded to the central rod or pushed through a hole drilled in it and bent over to hold it in place. The heat of the cylinder can be circulated by attaching a simple fan blade to the spinning shaft. This blows air down the hot sides of the canister, moving it towards the floor which is the most effective place for it circulate and heat the entire room. As the discs spin, the oil is pushed outwards and moves upwards, filling the top of the canister and building up some pressure there. This pressure can be relieved by running an external pipe from the top of the cylinder back to the bottom, allowing the oil to circulate freely. This has the decided advantage the circulating oil can be passed through a radiator as shown in the following diagram:  The central rod can be rotated by any convenient motor, conventional, Adams type, pulse-motor, permanent magnet motor, or whatever. An alternative to this style of operation, is to use the rotating motor to spin a ring of permanent magnets positioned close beside a thick aluminium plate. The eddy currents cause very strong heating of the aluminium plate which then can have air blown across it to provide space heating. The Peter Davey Heater. During World War II, Peter Daysh Davey, of Christchurch, New Zealand, a fighter pilot and musician, designed and built an unusual water heater. This design is not particularly well known and information is fairly thin on the ground, however, the basic principle and design details are known.  The device is intended to operate on the New Zealand mains power supply of 220 volts 50 Hz and a requirement of the apparatus is that it resonates at that 50Hz frequency. Resonance is a frequent requirement of free-energy systems, and the need for it is often overlooked by people who attempt to replicate free-energy devices. Properly built and tuned, this heater is said to have a COP of 20, which means that twenty times as much heat is produced by the device, compared to the amount of electrical power required to make it operate. This power gain is caused by additional energy being drawn from the immediate environment and it is very important as the largest use of energy in cool climates tends to be that used for heating. If that can be reduced by a serious amount, then your annual power costs should be much lower as a result of it. Peter was granted a New Zealand patent for his heater on 12th December 1944 but he found that after the war, the opposition from the utility companies was so great that it prevented him from going into commercial production with it. For fifty years, Peter kept up his attempts to get sufficient approval to bring his heater to the marketplace, but the opposition finally won and he never managed it. The device comprises a hemispherical resonant cavity, formed from two metallic dome shapes, both of which resonate at 50Hz. Initially, Peter used two bicycle bells and he found that when submerged in water, the device brought the water to the boil in a very short time indeed. The construction is like this:  If construction were to use two identical hemispheres, then the cavity between them would be anything but even width throughout, but the resonance would be the same. On the other hand, if you want the resonant cavity between the two hemispheres to be of constant width, then the outer sphere needs to be markedly larger than the inner hemisphere. The outside of both hemispheres needs to be insulated unless mounted in such a way that it is not possible to touch the hemispheres, as each is attached to the mains. In the above diagram, the mains live wire 6, is fed through the connecting pipe 8, and clamped to the inside of the inner hemisphere 1, by nut 3 which screws on to the threaded section of tube 8. It is important that it is the live wire which is connected to hemisphere 1. The mains neutral wire 7, is also fed through the connecting tube 8, exits via a small hole and is clamped on to the outside of the outer hemisphere 2, by nut 5, also on the threaded section of tube 8. The two hemispheres are held apart by a spacing washer 4, which is made from a high-temperature non-conducting plastic. As the tube 8 connects electrically and mechanically to both mains wires via the two locking nuts 3 and 5, it is essential that this tube is constructed from an electrically non-conducting material such as plastic. As the tube will be in boiling water on a regular basis, it is also necessary that the tube material is also able to handle temperatures over 100o C (212o F), so possible materials include nylon and teflon. This washer is a key component of the heater and its thickness is key to the efficiency of the whole device. This thickness L, is the tuning control for the cavity. The outer hemisphere is about 8 mm greater in diameter than the diameter of the inner hemisphere. Allowing for the thickness of the metal of the bowl, the resonant cavity will therefore be about 3 mm or one eighth of an inch. The hemisphere 1 is also tuned to 50 Hz by grinding it carefully until it resonates freely at that frequency. Connecting a loudspeaker in series with a resistor of say, 100K ohms, will give a sound of the exact frequency with which this hemisphere needs to resonate. This tuning needs to be done with the unit fully assembled as the connections to the tube will alter the resonant frequency of the hemisphere. When this is being done, the resonance will be felt rather than heard, so hold the tube lightly so that it can resonate freely. The tuning is done by removing a small amount of metal from the face of hemisphere 1 and then testing for resonance again. When hemisphere 1 resonates well at the mains frequency, (roughly G two octaves below middle C on a keyboard), the search for high-efficiency heating is carried out by very small adjustments of the gap L. The adjustment of the gap L is carried out by very careful grinding down of the separating washer 4 and the result is best determined by measuring the length of time needed to boil a known volume of water and the current taken to do that. Repeated tests and recorded results, shows when the best gap has been reached and the highest efficiency achieved. The heater can, of course, be used to heat any liquid, not just water. This heater is unlike a standard kettle heating element. In the standard method, the water is not a part of the main current-carrying circuit. Instead, the mains power is applied to the heater element and the current flowing through the heater element causes it to heat up, and the heat is then conveyed to the water by conduction. In Davey’s heater, on the other hand, the current flow appears to be through the water between the two hemispheres. It seems likely that the actual heating is not produced by current flow at all, but from cavitation of the water caused by the resonating of the cavity between the two hemispheres. This technique is used in small jewelry cleaners where and audio frequency is applied to a cleaning fluid in a small container. A small amount of electrolysis will take place with the Davey heater as it in effect also forms a single parallel-connected electrolyser. The amounts should be very small as only 1.24 volts out of the 220 volts applied will be used in the electrolysis process. An early construction of the original heater is shown in the photograph below. The coin shown in the picture is 32 mm (1.25 inch) in diameter. The heater is submerged in water when it is being used, and it brings that water to the boil exceptionally quickly. The unit was tested by New Zealand scientists who were able to vouch for its performance, but who were unable to state exactly how its operation allowed it to output such a high level of heat for such a low level of electrical input. You will notice from the photograph, how carefully the electrical connections and outer bowl are insulated.  The original prototype which Peter made was constructed from the tops of two bicycle bells, only one of which was tuned to 50 Hz. This shows that the device will definitely work if the inner hemisphere is tuned correctly. You can find forum investigation here and more recent information here. Here is an interesting article from the Home Power web site. If you are interested in renewable power, then I strongly recommend that you visit their web site and consider subscribing to their magazine as they cover many practical topics using simple wording.  The initial goal of our project was to build a functional, permanent magnet alternator from scratch, primarily out of wood. When the alternator was together and working, it became clear that wind was the logical energy source for it. This unit (we call it the “Wood 103”) is not intended to be a permanent addition to a remote home energy system, but a demonstration of how simple it really is to produce energy from scratch—and to be a bit silly! Many home-made wind generator designs require a fully equipped machine shop to build. Our wooden version, built in a day, can be made with mostly local materials and simple hand tools in any remote corner of the world. The alternator design is well suited to hydroelectric, human, or animal power. We plan to use it for a series of magnet and electricity demonstrations at local schools, and for future experiments with different energy sources, windings, cores, poles, and rotors. This project will cost you only US $50–75, depending on what you pay for magnets and wire. Alternator Basics Electricity is simply the flow of electrons through a circuit. When a magnet moves past a wire (or a wire past a magnet), electrons within the wire want to move. When the wire is wound into a coil, the magnet passes by more loops of wire. It pushes the electrons harder, and can therefore make more electricity for us to harvest. The magnetic field can be supplied by either permanent magnets or electromagnets. All of our designs use permanent magnets. In a permanent magnet alternator (PMA), the magnets are mounted on the armature (also sometimes called the “rotor”), which is the part that spins. It is connected directly to the wind generator rotor (the blades and hub). There are no electrical connections to the armature; it simply moves the magnets. Each magnet has two poles, north (N) and south (S). The magnets are oriented in the armature so that the poles alternate N-S-N-S. The other half of a PMA is the stator, which does not move. It consists of an array of wire coils connected together. The coils in our stator alternate in the direction they are wound, clockwise (CW) and counter-clockwise (CCW). The coils and magnets are spaced evenly with each other. So when the north pole of a magnet is passing a clockwise coil, the south pole of the next magnet is passing the counter-clockwise coil next door, and so on. The coil cores are located inside or behind the coils, and help concentrate the magnetic field into the coils, increasing output. The cores must be of magnetic material, but also must be electrically non-conductive to avoid power-wasting eddy currents. The air gap is the distance between the spinning magnets and the stationary coils (between the armature and the stator), and must be kept as small as possible. But the spinning magnets must not be allowed to touch the coils, or physical damage to them will occur.  The more loops of wire that each magnet passes, the higher the voltage produced. Voltage is important, since until the alternator voltage exceeds the battery bank voltage, no electrons can flow. The sooner the alternator voltage reaches battery voltage or above in low winds, the sooner the batteries will start to charge. Increasing the number of turns of wire in each coil allows higher voltage at any given speed. But thinner wire can carry fewer electrons. Using thicker wire allows more electrons to flow, but physical size limits the number of turns per coil. This also explains why enamelled magnet wire is always used in coils. The enamel insulation is very thin, and allows for more turns per coil than does thick plastic insulation. Any alternator design is a compromise between the number of turns per coil, the wire size, and the shaft rpm. The electricity produced by an alternator is called “wild” alternating current (AC). Instead of changing direction at a steady 60 times per second like standard AC house current, its frequency varies with the speed of the alternator. Since we want to charge batteries, the wild AC is fed to them through a bridge rectifier, which converts AC to DC (direct current) for battery charging. The alternator may produce much higher voltages than the battery bank does, but the batteries will hold the system voltage from the wind generator down to their normal level when charging.   Design We had successfully converted AC induction motors into PMA wind generators before. But starting from scratch was truly a first-time experiment. Our design choices for wire size, number of windings, number of poles, blade pitch, and other factors were intuitive rather than calculated. Every wind generator, waterwheel, and alternator we’ve built has produced usable energy, no matter how strange the design. The trick is matching the generator, rotor, and energy source. You can do a lot of study and calculation to get there. But if the design is quick, cheap, and easy to build, why not just make adjustments by observing the unit’s performance? If you try this project and change the wire size, magnet type, rotor design, and stator cores, you’d still be making usable energy and have a great starting point for further research. Just change one thing at a time until the unit performs to your satisfaction. We’re aware that many design improvements could be made to the Wood 103—and we hope that others will experiment with variations. Wooden Alternator The biggest problem with building most wind generator designs at home is the need for machine tools -usually at least a metal lathe is required. Headquarters for our business, Otherpower.com, is high on a mountain, 11 miles (18 km) past the nearest utility line. We are lucky enough to have basic tools up here, but many folks around the world don’t. That’s the main reason we used so much wood in this design.  It is possible to build human-powered woodworking tools in almost any location. With some patience, only simple hand tools are required for this project. If you want to build it in a day, though, a lathe, drill press, band saw, and power planer can be very helpful! Building the Armature The key to the Wood 103’s armature is the neodymium-iron-boron (NdFeB) magnets. They are the strongest permanent magnets available. Ours are surplus from computer hard drives. They are curved, and measure about 13/4 by 13/8 by 1/4 inch thick (44 x 35 x 6 mm). Eight fit together in a 37/8 inch (9.8 cm) diameter ring. That’s why we chose this particular diameter for the armature.  The magnets are available with either the north or south pole on the convex face. For this project, you will need four of each configuration. Don’t start tearing your computer apart to get these, though! They are from very large hard drives, and you won’t find any inside your computer. Check the Access section at the end of this article for suppliers. To construct the armature, we laminated plywood circles together with glue. The 37/8 inch (9.8 cm) diameter wooden cylinder is 33/4 inches (9.5 cm) long, with a 13/4 inch (4.4 cm) wide slot cut into it 1/4 inch (6 mm) deep to tightly accept the magnets. To assure that the magnets would be flush with the armature surface, we cut the plywood disks a bit oversized, and turned them down on the lathe to the proper diameter. The same procedure was used to cut the magnet slot to exactly the right depth. Using a firm grip, we carefully press-fit and epoxied the magnets into place. Remember that these magnets come in two different configurations—north pole on the convex face and south pole on the convex face. The magnets must have alternating poles facing out, and this is how they naturally want to align themselves. Next, we drilled the shaft hole through the centre of the armature using a lathe, though it could certainly be done with a hand drill if you are careful to align it perfectly. We roughed up the surface of the shaft with a file before epoxying it into the hole. It should be a very tight fit—we had to gently tap it through with a hammer. This may not be strong enough, and it might be wise to actually pin the armature to the shaft. Time will tell! Construction without a Lathe We did cheat by using a lathe to shape the armature, but a coping saw and sandpaper would work just fine. If a lathe is not available, our suggestion is to first cut out the disks, making sure that some of them (enough to stack up to 13/4 inches; 4.4 cm) are 1/4 inch (6 mm) smaller in diameter than the rest. Once assembled, the armature will then have a recessed slot for the magnets. Otherwise some means of “lathing” the slot will have to be devised. It could be done on the alternator’s pillow blocks with a sanding block mounted below, or in a drill press. It would also be wise to first drill a shaft hole into each plywood disk, and then assemble, glue, and clamp all the plywood disks together on the shaft before turning. Building the Pillow Blocks The pillow block bearings were made from pine, since that’s the hardest wood we have available up here on the mountain. Certainly hardwood would be much better. First we drilled a hole slightly under 3/8 inch (9.5 mm) diameter in each pillow block. Using a gas stove burner, we heated the shaft to almost red hot, and forced it through the holes. This gave a good tight fit, hardened the wood, and made a layer of carbon on the inside for better lubrication. We drilled a small hole in the top of each pillow block, down into the shaft hole, so the bearings can be greased  After pressing the hot shaft through the pillow blocks, we were very pleased with how freely the armature turned and how little play there was. In a slow waterwheel design, wood/carbon bearings would probably last for years. This wind generator is a actually a fairly high-speed unit, and real ball bearings would be a big improvement. Such bearings could be easily scavenged from an old electric motor of any kind. Wooden bearings were certainly simple, fast, and fun though!  Building the Stator The stator, on which the coils are wound, is made up of two identical halves. Each half is made from 2 by 4 inch lumber, 6 inches long (5 x 10 x 15 cm). A semi-circular cut-out with a 5 inch diameter (12.7 cm) was made on each half. The tolerances are pretty tight, but this allows more than a 1/2 inch (13 mm) to fit the coils and core material inside. On the sides of the 2 by 4s, right over the cut-out, we of this type is often available from electronics stores or glued thin (1/8 inch; 3 mm) U-shaped plywood “half disks,” which have an inner diameter of 4 inches (10 cm) and an outer diameter of 6 inches (15 cm). They have slots cut large enough to accept the coils. These were made with a hand saw, 3/8 inch (9.5 mm) drill bit, and a rat tail file. The coils are wound in these slots, and the space inside and behind the coils is filled with the magnetite core material. There are four coils on each half of the stator, and they must be evenly spaced. Our twin stator halves are wound with #22 (0.64 mm diameter) enamelled copper magnet wire. Magnet wire of this type is often available from electronics stores or from electric motor repair shops. Each stator half contains four coils. Each coil is 100 turns, and every coil is wound in the opposite direction as its neighbour. It’s important to wind the coils neatly and tightly, using a wooden dowel to carefully press each winding loop into place.  Most common alternators use thin steel laminates as cores, to help concentrate the magnetic field through the coils. Magnetism in motion pushes the electrons around in the steel too. The laminates are insulated from each other to block these eddy currents, which would otherwise waste energy. These laminates are difficult to make in a home shop, so we chose dirt as our stator core—actually magnetite sand mixed with epoxy. It is not as effective as real laminates, but was very easy to use, and available for free by separating it from the dirt in our road. We mixed the magnetite with epoxy and simply spooned it into the open cores. If the cores were left empty (an “air core”) the alternator would still work, but with much less power. Magnetite is a common mineral, a type of iron oxide. It is a by-product of some gold mining operations, and can sometimes be purchased. As an alternative, we simply dragged a large neodymium magnet (just like the ones we used for the armature) around on our local dirt road on a string for a while, attracting all the ferrous sand, which stuck to the magnet.  We separated this somewhat magnetic sand into a pile, sifted it through a window screen, and sorted that with the magnet one more time. The remaining black sand sticking to the magnet was nearly pure magnetite. A quick test of any local dirt pile with a neodymium magnet should reveal whether your sand contains magnetite. If not, try dragging the magnet along the sandy bottom of a local river. Any deposits of black sand on the river bottom are most likely nearly pure magnetite. The clearance between the stator coils and the armature surface is very important. It must be extremely close (within 1/16 inch; 1.5 mm) without allowing the magnets in the armature to touch the stator. Our model is actually a bit sloppy—the clearances are more like an 1/8 inch (3 mm). Tighter tolerances would produce more power. Wiring Configuration The completed stator consists of two identical sets of four coils. For our wind generator, we connected the stator halves in parallel for more current (amperage). Connecting them in series would double the voltage produced, but halve the amperage. For low wind speeds, a series connection would be the best—the alternator would reach charging voltage at slower speeds. At higher speeds, a parallel connection is optimum for producing the most amperage. An ideal system would contain a regulator that switched the stator connections from series to parallel when the unit began to spin fast enough. As is the case with many home-brew and commercial wind turbines, we eliminated this entirely, sacrificing a small amount of efficiency for much greater simplicity and reliability. Many people have experimented with such regulators, both solid state and mechanical. Alternator Performance We were really surprised by this alternator’s performance. We could easily spin it with our fingers and get 12 volts or higher. A cordless drill attached to the shaft would light up a 25 watt, 12 V DU light bulb easily. This might not seem breath-taking, but considering the simplicity of the project and one-day construction time, we were quite impressed. Our 100 watt rating for the Wood 103 is probably right on, considering the performance we got during testing, and the way commercial wind generator manufacturers rate their products. Our data acquisition system was pretty simple - multimeters and people with pencils and paper to watch them and record measurements. With a series connection between the stator halves, the unit reached charging voltage for 12 volt batteries at around 300 rpm. With the stator in parallel, it took around 600 rpm to start charging. When installed in our wind machine, the parallel connection gave us 4.8 amps output in a 25 mph (11 m/s) wind. Building the Frame To stay with the style of this project, we chose to build the rest of the wind generator out of wood too. It’s a very simple design and should be self-explanatory. It’s all glued and pinned with dowels. No bolts are used except to connect the alternator to the frame. We admit that we cheated here! We did not make any provision for over-speed control, since this was intended to be a demonstration unit for all energy sources, not just wind. A canted tail and spring assembly could be added to control speed during high winds. And, of course, making the frame out of surplus steel or aluminium angle would give great improvements in durability. We also did not include slip rings for power transmission as the wind generator yaws. Instead, we used flexible wire for the first few feet, letting it hang in a loose loop. A piece of aircraft cable cut slightly shorter than the power cable was attached, so if the power wire gets wrapped around the pole too tightly, the connections won’t pull loose. Our normal winds are usually from one direction, and designs without slip rings seem to work fine up here. Wrapping the power wire around the pole is only rarely a problem, and this strain relief cable prevents any damage. Our experience is that if the power cable does wind up all the way, it will eventually unwind itself.  Designing the Rotor The “rotor” here refers to the blades and hub of the wind generator. We don’t profess to be experts in blade design. Once again, we chose our starting point intuitively rather than trying to calculate the proper blades to match our alternator’s power curve. Since the blade carving process took us less than an hour for the whole set of three, we figured that any design changes would be quick and easy to make. However, because we glued the blades to the hub, a new hub will be necessary for any blade changes. There’s a great deal of information out there about building blades. Hugh Piggott’s Web site and his Brake-drum Wind Generator plans are some of the best sources around. The rotor was built from 3/4 inch by 4 inch (19 mm x 100 mm) pine lumber. Each blade is 3 1/2 inches (90 mm) wide at the base and 2 1/2 inches (64 mm) wide at the tip. The three blades are 2 feet long (600 mm), for a total diameter of 4 feet (1.2 m). The pitch of the blades is 10 degrees at the hub, and 6 degrees at the tip. The hub is made from 2 inch (50 mm) thick wood, press-fit and glued to the roughed-up shaft with epoxy. The blades are held on to the hub by one small nut at the end of the shaft, and several wooden pins with glue. Carving the Blades To prepare the blades for carving, we simply drew a few lines so that we knew what material to remove. Each blade starts out life as a 2 foot (0.6 m) long, 1 x 4 inch (25 mm x 100 mm). Starting from the leading edge of the blade at the hub, we simply used a protractor to lay out how far into the wood, 10 degrees of pitch would take us at the trailing edge - about 5/8 inch (16 mm). At the tip, the pitch is about 6 degrees, so we removed about 3/8 inch (9.5 mm) of material from the trailing edge. We made both marks, and connected the two with a line. We then simply took a power planer, and followed the cut depth line all the way up the blade.   For better accuracy (or if you don’t have a power planer), you can use a hand saw to make cuts across the blade every inch or so, down to the cut depth line on the trailing edge and not cutting at all on the leading edge. Using a hammer and chisel, it’s easy to break out the chunks of wood to the proper depth. Then smooth the blade down to the proper angle with a hand plane. When the saw kerfs disappear, the blade pitch is correct. The blade width taper occurs on the trailing edge. We simply used a saw to cut the first taper, and used that first blade as a template for cutting the others. No calculations were made for the airfoil shape on the other side of the blades. We picked a likely looking profile and started cutting with the power planer. A hand planer is fine for this process, too. After everything looked good and even, we sanded the blades and treated them with linseed oil. Balancing the Blades To avoid vibration problems and enable easy starting, we made some effort to balance the blades. We considered them reasonably balanced when each blade weighed the same (about 8 ounces; 227 g) and had the same centre of gravity. Adjustments can be made quickly with a planer. Once this is done, and all three blades are assembled on the hub, balance can be double-checked by spinning the rotor and making sure it has no tendency to stop in any one place. This is a quick process, and we certainly were not concerned about great precision here. As it turned out, a small effort in balancing the blades yielded good results, and the machine seems well balanced and vibration free. Truly, one could write an entire book on blade design, and it can get complicated. Don’t worry, though. It is possible to make a very basic blade that will work quite effectively. Often a simple blade with a constant 5 degree pitch from hub to tip and a reasonable airfoil on the backside will work very nicely. If you are interested, explore the books and Web sites listed at the end of this article for more information on blade design. Testing For testing, we strapped the Wood 103 to our trusty Model A Ford. The Model A serves as a reliable daily driver, and with the bracket we made, it makes an excellent testing facility for wind turbines. It has a perfectly accurate speedometer, which has been carefully checked by the Fort Collins, Colorado Police Department’s radar machines! We carry a 12 volt battery, a voltmeter, an ammeter, and pencil and paper in the test vehicle. On a still day, we can observe the speedometer and take accurate windspeed versus output measurements on any wind turbine. We’ve used this rig with props over 8 feet (2.4 m) in diameter. The cost of a good Model A (about US $4,000 if you don’t mind a jalopy) is not included in the price of this project! Wind generators should be installed high above human activity. For testing purposes, we've run our generator on low towers within reach of people, and on our Model A. Wind generators have parts that spin very fast! The blades could probably take your head off in a high wind if you were silly enough to walk into them. Make all installations well out of reach of curious organisms. You should treat any wind generator with a great deal of respect. This is not a joking matter, though we always shout “Clear prop!” before we fire up the test vehicle...   Improvements Many improvements could be made to this design. But the intention was to use mostly wood and hand tools, and keep it fast and simple. The wooden alternator is easy and quick to build, but for longest life, it would need to be protected from rain and snow. Maybe a small shingled roof over it? Using real ball bearings would help friction loss and longevity a bunch. A metal frame and tail would improve high-wind survivability significantly. A furling system to keep the Wood 103 from destroying itself during a gale would be a great addition too. We plan to experiment with many improvements, and we hope this project piques the interest of others too. Trade-Offs Designing and building a permanent magnet alternator involves a long series of trade-offs. For example, thicker wire in the windings would give more possible current, but less room for windings and hence lower voltage at the same rpm. Ceramic magnets might be cheaper, but would give far less power than neodymium magnets. Series wiring on the stator would allow lower rpm at charging voltage, but parallel gives better charging current—and a regulator to switch between the two would be complicated. Using steel laminates instead of air or dirt stator cores would produce more power, but laminate production is extremely difficult. The trade-offs involved in designing a complete wind generator (or water turbine, or bicycle generator) are even more lengthy and complicated. Wind speed, rotor diameter, number of blades, blade pitch, width and twist, optimum rpm for your winding configuration, generator diameter, and number of poles all factor into a perfect final design. Improvise, But Do it! We’ve tried to demonstrate how easy it is to produce electricity from scratch. Don’t let yourself get hung up on complicated formulas, calculations, and machine tools. Even if you make many changes to this simple design, you’ll still almost certainly have a unit that makes usable energy for charging batteries. Then, you can make small improvements until it performs exactly right for your application. And it could be powered by wind, falling water, a human on a bicycle, a dog on a treadmill, or a yak in a yoke! Access Dan Bartmann and Dan Fink, Forcefield, 2606 West Vine Dr., Fort Collins, CO 80521 • 877-944-6247 or 970-484-7257 • danb@otherpower.com danf@otherpower.com • www.otherpower.com Magnets, magnet wire, bridge rectifiers, free information, and a very active discussion board All Electronics, PO Box 567, Van Nuys, CA 91408 888-826-5432 or 818-904-0524 • Fax: 818-781-2653 allcorp@allcorp.com • www.allelectronics.com Magnets, rectifiers, and lots of electronics parts at great prices American Science and Surplus, 3605 Howard St., Skokie, IL 60076 • 847-982-0870 • Fax: 800-934-0722 or 847-982-0881 • info@sciplus.com • www.sciplus.com Magnets, magnet wire, surplus electronics, bearings, and other neat stuff Marlin P. Jones and Assoc., PO Box 530400, Lake Park, FL 33403 • 800-652-6733 or 561-848-8236 Fax: 800-432-9937 or 561-844-8764 • mpja@mpja.com www.mpja.com • Magnet wire, rectifiers, electronics, tools, test equipment Hugh Piggott, Scoraig Wind Electric, Scoraig, Dundonnell, Ross Shire, IV23 2RE, UK • +44 1854 633 286 • Fax: +44 1854 633 233 hugh.piggott@enterprise.net • www.scoraigwind.co.uk Wind generator and alternator designs, lots of free information about blade design and carving WindStuffNow, Edwin Lenz, 10253 S. 34th St., Vicksburg, MI 49097 • 616-626-8029 elenz@windstuffnow.com • www.windstuffnow.com Alternator designs, parts, useful formulas, free information, and blade design software American Wind Energy Association (AWEA) discussion board • http://groups.yahoo.com/group/awea-windhome • Join the list by sending a blank e-mail to: awea-wind-home-subscribe@yahoogroups.com www.awea.org Frank Herbert’s Windmill. As has been carefully explained by the above article, if a windmill of the blade variety is mounted low down then it is dangerous, and people on sailing boats have been killed by them. Also, if the blade arrangement is designed to operate well in low wind conditions, then it is not unusual for there to be a problem if the wind rises to gale force or higher, with some generator designs giving up and switching off entirely, even though the available free energy is at its highest level. This design by Frank Herbert is perfectly capable of being home-built and yet it overcomes these problems as well as being a high-efficiency wind turbine. It has an outside cage which prevents human access to the moving parts inside and the ‘cage’ is not just for protection but is there to enhance the performance of the device. In passing, windmills can be used to compress air and compressed air cylinders can be used to power vehicles and/or power electrical generators during periods of heavy power requirements. The following information is from Frank Herbert’s US Patent 4,142,822 of 1979:  The vertical housing 22 shown dotted here, surrounds the vertical power take-off shaft 26. The wind is allowed to flow through this housing at any angle, so there is no need for the housing to move. In the diagram above small discs 44 are shown at each end of the vertical shaft. These discs have arms 42 extending outwards to support a series of vertical vanes or pressure surfaces 24. For clarity, just one vane is shown through there will actually be many of these (rather like the cutting blades on a cylinder lawnmower). In reality, there will be no arms on the discs 42 as it is much easier just to have a full-width solid disc supporting the vanes. The outer housing has a series of vertical slats which are angled to direct the incoming wind on to the vanes at the best possible angle:  This top view of part of the device, shows the main mounting shaft 26 on which the top and bottom rotor discs are mounted. The red dots show the pivot points where the vanes 24 can turn to take the greatest advantage of the wind pressure. The incoming wind 36, is deflected by the slats of the housing 32, to give it a good angle when flowing through the device as well as keeping humans away from the spinning mechanism. As the vanes and slats are located all the way around shaft 26, sudden changes in wind direction and/or wind strength have no particular effect on this design as it operates with wind coming from any direction and no physical movement of any part of the device is needed for a change in wind direction. The vanes can have various different profiles and still work well. The shape shown above is the shape of an aircraft wing, where a force acting towards the curved surface is generated when air flows around the shape. This is not a particularly difficult shape to construct and it is very effective in an airflow (which is why it is used to lift aircraft off the ground). There can be any convenient number of vanes and a device built as shown above should be very effective.. As the overall efficiency is improved if there is no turbulence inside the device, Frank has found a method of minimising this. For this, he uses a mechanism which can alter the shape of the vanes when the windspeed gets high. The higher windspeed whirls the vanes around faster, causing higher ‘centrifugal’ forces on the vanes which Frank uses as follows. Weight 54 gets pushed across by the spin rate of the rotor.  This pushes against the spring 56, compressing it. The triangle link 59 moves upwards, pivoting at points 59a and 59c, and raising section 50 of the vane. This changes the shape of the vane as shown here:  The result of this changed shape is to reduce turbulence inside the device and raise the overall efficiency. Mead and Holmes. The US patent 4,229,661 dated 1980 from Claude Mead and William Holmes is entitled “Power Plant for Camping Trailer” proposes the use of a wind power generator to store compressed air for later use in providing household electrical current, and simultaneously charge batteries which can be used to drive the compressor in periods of very high electrical demand. There is also an option for a rapid system charge if AC mains power becomes available:  Solar Ovens. This information comes from http://solarcooking.org/plans/funnel.htm and ownership remains with the original authors and this material is reproduced here with their kind permission. How to Make and Use The Brigham Young University Solar Cooker/Cooler by Professor of Physics at Brigham Young University (BYU), with Colter Paulson, Jason Chesley, Jacob Fugal, Derek Hullinger, Jamie Winterton, Jeannette Lawler, and Seth, David, Nathan, and Danelle Jones.  Introduction A few years ago, I woke up to the fact that half of the people in the world must burn wood or dried dung in order to cook their food. It came as quite a shock to me, especially as I learned of the illnesses caused by breathing smoke day in and day out, and the environmental impacts of deforestation - not to mention the time spent by people (mostly women) gathering sticks and dung to cook their food. And yet, many of these billions of people live near the equator, where sunshine is abundant and free. So..... As a University Professor of Physics with a background in energy usage, I set out to develop a means of cooking food and sterilising water using the energy freely available from the sun. First, I looked at existing methods. The parabolic cooker involves a reflective dish which concentrates sunlight to a point where the food is cooked. This approach is very dangerous since the sun's energy is focused to a point which is very hot, but which cannot be seen. (Brigham Young University students and I built one which will set paper on fire in about 3 seconds!). I learned that an altruistic group had offered reflecting parabolas to the people living at the Altiplano in Bolivia. But more than once these parabolas had been stored next to a shed -- and the passing sun set the sheds on fire! The people did not want these dangerous, expensive devices, even though the Altiplano region has been stripped of fuel wood. The box cooker is basically an insulated box with a glass or plastic lid, often with a reflecting lid to direct sunlight into the box. Light enters through the top glass (or plastic), to slowly heat up the box. The problems with this design are that energy enters only through the top, while heat is escaping through all of the other sides, which have a tendency to draw heat away from the food. When the box is opened to put food in or take it out, some of the heat escapes and is lost. Also, effective box cookers tend to be more complicated to build than the funnel cooker. While studying this problem, I thought again and again of the great need for a safe, inexpensive yet effective solar cooker. It finally came to me at Christmastime a few years ago, a sort of hybrid between the parabola and the box cooker. It looks like a large, deep funnel, and incorporates what I believe are the best features of both the parabolic cooker and the box cooker. The first reflector was made at my home out of aluminium foil glued on to cardboard, then this was curved to form a reflective funnel. My children and I figured out a way to make a large cardboard funnel easily. (I'll tell you exactly how to do this later on.) The Solar Funnel cooker is safe and low cost, easy to make, yet very effective in capturing the sun's energy for cooking and pasteurising water -> Eureka! Later, I did extensive tests with students (including reflectivity tests) and found that aluminised Mylar was good too, but relatively expensive and rather hard to come by in large sheets. Besides, cardboard is found throughout the world and is inexpensive, and aluminium foil is also easy to come by. Also, individuals can make their own solar cookers easily, or start a cottage-industry to manufacture them for others. Prototypes of the Solar Funnel Cooker were tested in Bolivia, and outperformed an expensive solar box cooker and a “Solar Coolkit” while costing much less then either. Brigham Young University submitted a patent application, mainly to insure that no company would prevent wide distribution of the Solar Funnel Cooker. Brigham Young University makes no profit from the invention. (I later learned that a few people had had a similar idea, but with methods differing from those developed and shown here). So now I'm trying to get the word out so that the invention can be used to capture the free energy coming from the sun - for camping and for emergencies, yes, but also for every day cooking where electricity is not available and where even fuel wood is getting scarce. How it Works The reflector is shaped like a giant funnel, and lined with aluminium foil. (Easy to follow instructions will be given soon). This funnel is rather like the parabolic cooker, except that the sunlight is concentrated along a line (not a point) at the bottom of the funnel. You can put your hand up the bottom of the funnel and feel the sun's heat, but it will not burn you. Next, we paint a jar black on the outside, to collect heat, and place this at the bottom of the funnel. Or a black pot with a lid can be used. The black vessel gets hot, quickly, but not quite hot enough to cook with. We need some way to build up the heat without letting the outside air cool it. So, I put a cheap plastic bag around the jar -- and, the solar funnel cooker was born! The plastic bag, available in grocery stores as a "poultry bag", replaces the cumbersome and expensive box and glass lid of solar box ovens. You can use the plastic bags used in American stores to put groceries in, as long as they let a lot of sunlight pass. (Dark- coloured bags will not do). I recently tested a bag used for fruits and vegetables, nearly transparent and available free at American grocery stores, that works great. This is stamped "HDPE" for high-density polyethylene on the bag (ordinary polyethylene melts too easily). A block of wood is placed under the jar to help hold the heat in. (Any insulator, such as a hot pad or rope or even sticks, will also work). A friend of mine who is also a Physics Professor did not believe I could actually boil water with the thing. So I showed him that with this new "solar funnel cooker" I was able to boil water in Utah in the middle of winter! I laid the funnel on its side since it was winter and pointed a large funnel towards the sun to the south. I also had to suspend the black cooking vessel -- rather than placing it on a wooden block. This allows the weaker sun rays to strike the entire surface of the vessel. Of course, the Solar Funnel works much better outside of winter days, that is, when the UV index is 7 or greater. Most other solar cookers will not cook in the winter in northern areas (or south of about 35 degrees, either). I thought that a pressure cooker would be great. But the prices in stores were way too high for me. Wait, how about a canning jar? These little beauties are designed to relieve pressure through the lid -- a nice pressure cooker. And cooking time is cut in half for each 10ºC we raise the temperature (Professor Lee Hansen, private communication). I used one of my wife's wide-mouth canning jars, spray-painted (flat) black on the outside, and it worked great. Food cooks faster when you use a simple canning jar as a pressure cooker. However, you can also put a black pot in the plastic bag instead if you want. But don't use a sealed container with no pressure release like a mayonnaise jar -- it can break as the steam builds up (I've done it)! How to Build Your Own Solar Funnel Cooker What You will Need:

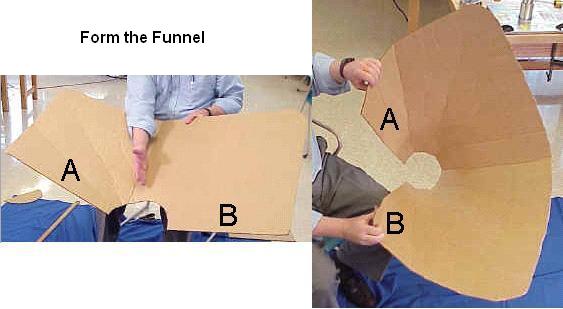

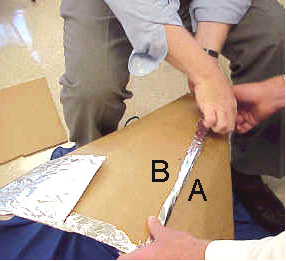

Cut a half circle out of the cardboard, along the bottom as shown below. When the funnel is formed, this becomes a full-circle and should be wide enough to go around your cooking pot. So for a 7" diameter cooking pot, the radius of the half-circle is 7". For a quart canning jar such as I use, I cut a 5" radius half-circle out of the cardboard.  To form the funnel, you will bring side A towards side B, as shown in the figure. The aluminium foil must go on the INSIDE of the funnel. Do this slowly, helping the cardboard to the shape of a funnel by using one hand to form creases that radiate out from the half-circle. Work your way around the funnel, bending it in stages to form the funnel shape, until the two sides overlap and the half-circle forms a complete circle. The aluminium foil will go on the INSIDE of funnel. Open the funnel and lay it flat, "inside up", in preparation for the next step. Glue Foil to Cardboard  Apply glue or adhesive to the top (inner) surface of the cardboard, then quickly apply the aluminium foil on top of the glue, to affix the foil to the cardboard. Make sure the shiniest side of the foil is on top, since this becomes your reflective surface in the Funnel. I like to put just enough glue for one width of foil, so that the glue stays moist while the foil is applied. I also overlap strips of foil by about 1" ( or 2 cm). Try to smooth out the aluminium foil as much as you reasonably can, but small wrinkles won't make much difference. If cardboard is not available, one can simply dig a funnel-shaped hole in the ground and line it with a reflector, to make a fixed solar cooker for use at mid-day. Join side A to side B to keep the funnel together.  The easiest way to do this is to punch three holes in the cardboard that line up on side A and side B (see figure). Then put a metal brad through each hole and fasten by pulling apart the metal tines. Or you can use a nut-and-bolt to secure the two sides (A & B) together. Be creative here with what you have available. For example, by putting two holes about a thumb-width apart, you can put a string, twine, small rope, wire or twist-tie in one hole and out the other, and tie together. When A and B are connected together, you will have a "funnel with two wings". The wings could be cut off, but these help to gather more sunlight, so I leave them on. Tape or glue a piece of aluminium foil across the hole at the bottom of the funnel, with shiny side in.  This completes assembly of your solar funnel cooker. For stability, place the funnel inside a cardboard or other box to provide support. For long-term applications, one may wish to dig a hole in the ground to hold the Funnel against strong winds. Final Steps At this stage, you are ready to put food items or water into the cooking vessel or jar, and put the lid on securely. (See instructions on food cooking times, to follow). Place a wooden block in the INSIDE bottom of the cooking bag. I use a piece of 2” x 4” board which is cut into a square nominally 4" x 4" by 2" thick. Then place the cooking vessel containing the food or water on top of the wooden block, inside the bag. Next, gather the top of the bag in your fingers and blow air into the bag, to inflate it. This will form a small "greenhouse" around the cooking vessel, to trap much of the heat inside. Close off the bag with a tight twist tie or wire. Important: the bag should not touch the sides or lid of the cooking vessel. The bag may be called a "convection shield," slowing convection-cooling due to air currents. Place the entire bag and its contents inside the funnel near the bottom as shown in the Photographs. Place the Solar Funnel Cooker so that it Faces the Sun Remember: Sunlight can hurt the eyes: so please wear sunglasses when using a Solar Cooker! The Funnel Cooker is designed so that the hot region is deep down inside the funnel, out of harm's way.  Put the Solar Funnel Cooker in the sun pointing towards the sun, so that it captures as much sunlight as possible. The design of the funnel allows it to collect solar energy for about an hour without needing to be re-positioned. For longer cooking times, readjust the position of the funnel to follow the sun's path. In the Northern Hemisphere, it helps to put the Solar Funnel Cooker in front of a south-facing wall or window as this reflects additional sunlight into the funnel. A reflective wall is most important in locations farther from the equator and in winter. In the Southern Hemisphere, put the Solar Funnel Cooker in front of a North-facing wall or window to reflect additional sunlight into your cooker. After Cooking Remember that the cooking vessel will be very hot: so use cooking pads or gloves when handling it! If you are heating water in a canning jar, you may notice that the water is boiling when the lid is first removed - it gets very hot! Open the plastic cooking bag by removing the twist-tie. Using gloves or a thick cloth, lift the vessel out of the bag and place it on the ground or table. Carefully open the vessel and check the food, to make sure it has finished cooking. Let the hot food cool before eating. Helpful Hints Avoid leaving fingerprints and smudges on the inside surface of the cooker. Keep the inner surface clean and shiny by wiping occasionally with a wet towel. This will keep the Solar Funnel Cooker working at its best. If your funnel gets out-of-round, it can be put back into a circular shape by attaching a rope or string between opposite sides which need to be brought closer together. For long-term applications, a hole in the ground will hold the Funnel Cooker securely against winds. Bring the funnel inside or cover it during rain storms. The lids can be used over and over. We have had some trouble with the rubber on some new canning-jar lids becoming soft and "sticky." "Ball canning lids" do not usually have this problem. Running new lids through very hot water before the first use seems to help. The lids can be used over and over if they are not bent too badly when opened (pry off lid carefully). The jar can be suspended near the bottom of the funnel using fishing line or string (etc.), instead of placing the jar on a block of wood. A plastic bag is placed around the jar with air puffed inside, as usual, to trap the heat. The suspension method allows sunlight to strike all surfaces of the jar, all around, so that heats faster and more evenly. This suspension method is crucial for use in winter months. Adjust the funnel to put as much sunlight onto the cooking jar as possible. Look at the jar to check where the sunlight is hitting, and to be sure the bottom is not in the shadows. For long cooking times (over about an hour), readjust the position of the funnel to follow the sun's path. During winter months, when the sun is low on the horizon (e.g., in North America), it is helpful to lay the funnel on its side, facing the sun.  Tests in Utah I have personally used the Solar Funnel Cooker to cook lunches over many weeks. My favourite foods to cook are potatoes (cut into logs or slices) and carrot slices. Vegetables cook slowly in their own juices and taste delicious. I also make rice, melted cheese sandwiches, and even bread in the Solar Funnel Cooker. I usually put the food out around 11:30 and let it cook until 12:45 or 1 pm, just to be sure that it has time to cook. I've never had any food burn in this cooker. I have also cooked food in the mountains, at an altitude of around 8,300 feet. If anything, the food cooked faster there - the sunlight passes through less atmosphere at high altitudes. I find that people are surprised that the sun alone can actually cook food. And they are further pleasantly surprised at the rich flavours in the foods which cook slowly in the sun. This inexpensive device does it! Students at Brigham Young University have performed numerous tests on the Solar Funnel Cooker along with other cookers. We have consistently found much faster cooking using the Solar Funnel Cooker. The efficiency/cost ratio is higher than any other solar cooking device we have found to date. Mr. Hullinger also performed studies of transmissivity, reflectivity and absorptivity of alternate materials which could be used in the Solar Funnel Cooker. While there are better materials, such as solar-selective absorbers, our goal has been to keep the cost of the Solar Cooker as low as possible, while maintaining safety as a first priority. Tests in Bolivia The BYU Benson Institute organised tests between the Solar Funnel Cooker and the "old-fashioned" solar box oven. The solar box oven cost about $70 and was made mostly of cardboard. It took nearly two hours just to reach water pasteurisation temperature. The Bolivian report notes that "food gets cold every time the pots are taken from and into the oven." The solar box oven failed even to cook boiled eggs. (More expensive box cookers would hopefully work better.)  An aluminised-mylar Solar Funnel Cooker was also tested in Bolivia, during the Bolivian winter. Water pasteurisation temperature was reached in 50 minutes, boiled eggs cooked in 70 minutes, and rice cooked in 75 minutes. The Bolivian people were pleased by the performance. So were we! (La Paz, Bolivia, August, 1996). I also donated two dozen solar funnel cookers for people in Guatemala. These were taken there by a group of doctors going there for humanitarian service. The people there also liked the idea of cooking with the sun's free energy. For an aluminised-Mylar Solar Funnel Cooker kit, please contact CRM (licensed manufacturer) at +1 (801) 292-9210. Water and Milk Pasteurisiation Contaminated drinking water or milk kills thousands of people each day, especially children. The World Health Organisation reports that 80% of illnesses in the world are spread through contaminated water. Studies show that heating water to about 65º - 70º C (150º F) is sufficient to kill coliform bacteria, rotaviruses, enteroviruses and even Giardia. This is called pasteurisation. Pasteurisation depends on how hot and how long water is heated. But how do you know if the water got hot enough? You could use a thermometer, but this would add to the cost, of course. When steam leaves the canning jar (with lid on tight) and forms "dew" on the inside of the cooking bag, then the water is probably pasteurised to drink. (The goal is to heat to 160º Fahrenheit for at least six minutes.) With a stripe of black paint scraped off the jar, one can look through the bag and into the jar and see when the water is boiling - then it is safe for sure. Think of all the lives that can be saved simply by pasteurising water using a simple Solar Cooker! Safety Safety was my first concern in designing the Solar Funnel Cooker, then came low cost and effectiveness. But any time you have heat you need to take some precautions.

Cooking with the Solar Funnel Cooker What do you cook in a crock pot or moderate-temperature oven? The same foods will cook about the same in the Solar Funnel Cooker - without burning. The charts below give approximate summer cooking times. The solar cooker works best when the UV index is 7 or higher (Sun high overhead, few clouds). Cooking times are approximate. Increase cooking times for partly-cloudy days, sun not overhead (e.g., wintertime) or for more than about 3 cups of food in the cooking jar. Stirring is not necessary for most foods. Food generally will not burn in the solar cooker. Vegetables (Potatoes, carrots, squash, beets, asparagus, etc.) Preparation: No need to add water if fresh. Cut into slices or "logs" to ensure uniform cooking. Corn will cook fine with or without the cob. Cooking Time: About 1.5 hours Cereals and Grains (Rice, wheat, barley, oats, millet, etc.) Preparation: Mix 2 parts water to every 1 part grain. Amount may vary according to individual taste. Let soak for a few hours for faster cooking. To ensure uniform cooking, shake jar after 50 minutes. CAUTION: Jar will be hot. Use gloves or cooking pads. Cooking Time: 1.5-2 hours Pasta and Dehydrated Soups Preparation: First heat water to near boiling (50-70 minutes). Then add the pasta or soup mix. Stir or shake, and cook 15 additional minutes. Cooking Time: 65-85 minutes Beans Preparation: Let tough or dry beans soak overnight. Place in cooking jar with water. Cooking Time: 2-3 hours Eggs Preparation: No need to add water. Note: If cooked too long, egg whites may darken, but taste remains the same. Cooking Time: 1-1.5 hours, depending on desired yolk firmness. Meats (Chicken, beef, and fish) Preparation: No need to add water. Longer cooking makes the meat more tender. Cooking Times: Chicken: 1.5 hours cut up or 2.5 hours whole; Beef: 1.5 hours cut up or 2.5-3 hours for larger cuts; Fish: 1-1.5 hours Baking Preparation: Times vary based on amount of dough. Cooking Times: Breads: 1-1.5 hours; Biscuits: 1-1.5 hours; Cookies: 1 hour Roasted Nuts (Peanuts, almonds, pumpkin seed, etc.) Preparation: Place in jar. A little vegetable oil may be added if desired. Cooking Time: About 1.5 hours MRE's and pre-packaged foods Preparation: For foods in dark containers, simply place the container in the cooking bag in place of the black cooking jar. Cooking Times: Cooking time varies with the amount of food and darkness of package. How to Use the Solar Funnel as a Refrigerator/Cooler A university student (Jamie Winterton) and I were the first to demonstrate that the Brigham Young University Solar Funnel Cooker can be used - at night - as a refrigerator. Here is how this is done: The Solar Funnel Cooker is set-up just as you would during sun-light hours, with two exceptions:

During the day, the sun's rays are reflected on to the cooking vessel which becomes hot quickly. At night, heat from the vessel is radiated outward, towards empty space, which is very cold indeed (a "heat sink"). As a result, the cooking vessel now becomes a small refrigerator. We routinely achieve cooling of about 20º F (10º C) below ambient air temperature using this remarkably simple scheme. In September 1999, we placed two funnels out in the evening, with double-bagged jars inside. One jar was on a block of wood and the other was suspended in the funnel using fishing line. The temperature that evening (in Provo, Utah) was 78º F (25.5º C). Using a Radio Shack indoor/outdoor thermometer, a BYU student (Colter Paulson) measured the temperature inside the funnel and outside in the open air. He found that the temperature of the air inside the funnel dropped quickly by about 15º F (8º C), as its heat was radiated upwards in the clear sky. That night, the minimum outdoor air temperature measured was 47.5º F (8.6º C) - but the water in both jars had ICE. I invite others to try this, and please let me know if you get ice at 55 or even 60 degrees outside air temperature (minimum at night). A black PVC container may work even better than a black-painted jar, since PVC is a good infrared radiator - these matters are still being studied. I would like to see the "Funnel Refrigerator" tried in desert climates, especially where freezing temperatures are rarely reached. It should be possible in this way to cheaply make ice for Hutus in Rwanda and for aborigines in Australia, without using any electricity or other modern "tricks." We are in effect bringing some of the cold of space to a little corner on earth. Please let me know how this works for you. Conclusion: Why We Need Solar Cookers The BYU Funnel Cooker/Cooler can: