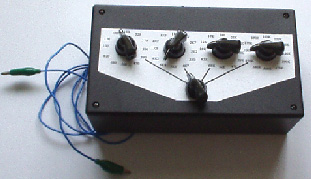

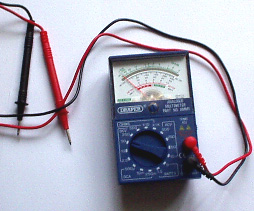

| Introduction This document is not an in-depth presentation of the subject of electronics. Instead, it is intended to give you sufficient (empirical) knowledge of the subject to be able to understand, design and build simple circuits such as the control circuits used with the ‘Free Energy’ devices described in the later parts of this document. Disclaimer This material is provided for information purposes only. Should you decide to attempt construction of some device based on information presented here and injure yourself or any other person, I am not liable in any way. To clarify this; should you construct something in a heavy box and drop it on your toe, I am not liable for any injury you may sustain (you should learn to be more careful). If you attempt to construct some electronic circuit and burn yourself with the soldering iron, I am not liable. Also, I strongly recommend that unless you are expert in electronics, you do not construct any device using, or producing more than 12 Volts - high voltage circuits are extremely dangerous and should be avoided until you gain experience or can obtain the help and supervision of a person experienced in constructing high voltage circuits. Voltage Voltage is the key to understanding electronics. Without voltage, nothing happens in electronics. What is it? Nobody knows. We know how to generate it. We know what it does. We know how to measure it, but nobody knows what it actually is. It is also called “Electro Motive Force” or “EMF” which is no help whatsoever in knowing what it is. That, is roughly equivalent to saying “the thing that pushes is the thing that pushes” - very true but absolutely no help whatsoever. OK, having admitted that we really don't know what it is, we can start to say the things we do know about it: A new battery has a voltage between its terminals. This voltage is said to cause a current to flow through any complete electrical circuit placed across it. The current flowing through the circuit can cause various things to happen such as creating light, creating sound, creating heat, creating magnetism, creating movement, creating sparks, etc., etc. By using the current caused by a voltage, a device called a ‘Voltmeter’ can indicate how big the voltage is. The bigger the voltage, the bigger the current and the bigger the display on the voltmeter. The voltmeter can have a numerical display where you read the voltage directly from the display, or it can be an ‘analogue’ voltmeter where the voltage is shown by the position of a needle on a scale. The size of the voltage is stated in ‘Volts’ which is a unit of measurement named after the man Volta who introduced voltage to the world (it was always there, we just did not know about it). Voltages add up if they are connected the same way round, i.e. with the + terminals all facing the same way:  The physical size of the battery usually determines the length of time it can supply any given current - the bigger the battery, the longer it can provide any given current. A battery is constructed from a number of ‘cells’. The number of cells in the battery controls the voltage of the battery. For example, an ‘AA’ size battery (what used to be called a ‘penlight’ battery) has a single ‘cell’ and so produces 1.5 Volts when new. The very much larger and heavier ‘D’ battery also has just one cell and so it also produces 1.5 Volts when new. The difference (apart from the higher cost of the ‘D’ cell) is that the larger cell can provide a much higher current if both batteries are discharged over the same period of time. There are several different types of battery construction. A rechargeable NiCad battery has a single cell but its construction method means that it produces about 1.35 Volts when fully charged. In passing, NiCad batteries have a ‘memory’ characteristic which means that if they are recharged before they are fully discharged, then the next time they are discharged they run out of power at the voltage level it had when the last charging was started. Consequently, it is a good idea to fully discharge a NiCad battery before charging it again. Car and motorcycle batteries are described as Lead/Acid batteries. This type of construction is not very convenient being large, heavy and potentially corrosive. The big advantages are the ability to provide very high currents and giving 2.0 Volts per cell. These batteries are normally produced as 6 Volt or 12 Volt units. The Amp-Hours for lead/acid car batteries is usually quoted for a 20 hour discharge period, so a fully charged, new, 20 AHr battery can provide 1 Amp for 20 hours of continuous use. That battery loaded to give 5 Amps, will not provide that current for 4 hours but might only last 2 hours, or perhaps a little better. The manufacturers literature should give an indication of the performance, but if it is important, run your own test to see how the battery actually works in practice. “Mains units” are known in the electronics world as “Power Supply Units” or “PSUs” for short. These convert the mains voltage (220 Volts in UK, 110 Volts in USA) to some convenient low voltage; 12 Volts, 9 Volts, 6 Volts, or whatever is needed. A mains unit can provide several different voltages simultaneously. Resistance Being familiar with Voltage and Resistance is the key to understanding electronic circuitry. Resistance is a measure of how difficult it is for current to flow through something. Some materials such as glass, ceramics, wood and most plastics do not easily carry a current and so are considered to be ‘insulators’. That is why you will see power lines hung from their pylons by a series of ceramic discs. Current flows easily through metals, especially along the surface of the metal, so cables are made from metal wires surrounded by a layer of plastic insulation. The higher grade cables have wire cores made up of many small-diameter strands as this increases the surface area of the metal for any given cross-sectional area of the metal core (it also makes the cable more flexible, and generally, more expensive). There is a very important, third group of materials, silicon and germanium in particular, which fall between conductors and insulators. Not surprisingly, these are called ‘semi-conductors’ and the amount of current they can carry depends on the electrical conditions in which they are placed. Much, much more about this later on. While a metal wire carries current very well, it is not perfect at the job and so has some ‘resistance’ to current flowing through it. The thicker the wire, the lower the resistance. The shorter the wire, the lower the resistance. The first researchers used this characteristic to control the way circuits operated. Sometimes, as higher resistances were needed, the researcher used to need long lengths of wire which would get tangled up. To control the wire, a board with nails along each side was used and the wire wound backwards and forwards across the board like this:  When drawing a circuit diagram, the researcher would sketch the wire on the board giving a zig-zag line which is still used today to represent a ‘resistor’ although different methods of construction are now used. An alternative symbol for a resistor is a plain rectangle as shown above. If a resistor is connected across a battery, a circuit is formed and a current flows around the circuit. The current cannot be seen but that does not mean that it is not there. Current is measured in ‘Amps’ and the instrument used to display it is an ‘ammeter’. If we place an ammeter in the circuit, it will show the current flowing around the circuit. In passing, the ammeter itself, has a small resistance and so putting it in the circuit does reduce the current flow around the circuit very slightly. Also shown is a bulb. If the current flowing around the circuit is sufficiently high and the bulb chosen correctly, then the bulb will light up, showing that current is flowing, while the ammeter will indicate exactly how much current is flowing:  Shown on the right, is the way that this circuit would be shown by an electronics expert (the ‘Resistor’, ‘Ammeter’ and ‘Lamp’ labels would almost certainly not be shown). There are several different styles of drawing circuit diagrams, but they are the same in the basic essentials. One important common feature is that unless there is some very unusual and powerful reason not to do so, every standard style circuit diagram will have the positive voltage line horizontally at the top of the diagram and the negative as a horizontal line at the bottom. These are often referred to as the positive and negative ‘rails’. Where possible, the circuit is drawn so that its operation takes place from left to right, i.e. the first action taken by the circuit is on the left and the last action is placed on the right. Resistors are manufactured in several sizes and varieties. They come in ‘fixed’ and ‘variable’ versions. The most commonly used are the ‘fixed’ carbon ‘E12’ range. This is a range of values which has 12 resistor values which repeat: 10, 12, 15, 18, 22, 27, 33, 39, 47, 56, 68, 82 and then: 100, 120, 150, 180, 220, 270, 330, 390, 470, 560, 680, 820 and then: 1000, 1200, 1500, 1800, 2200, 2700, 3300, 3900, 4700, 5600, 6800, 8200, etc. etc. Nowadays, circuits often carry very little power and so the resistors can, and are, made in very small physical sizes. The higher the resistance value of a resistor, the less current will flow through it when a voltage is placed across it. As it can be difficult to see printing on small resistors clustered together on a circuit board and surrounded by other larger components, the resistor values are not written on the resistors, instead, the resistors are colour-coded. The unit of measurement for resistors is the ‘ohm’ which has a very small size. Most resistors which you encounter will be in the range 100 ohms to 1,000,000 ohms. The higher the resistance of any resistor, the smaller the current which will flow through it. The colour code used on resistors is: 0 Black 1 Brown 2 Red 3 Orange 4 Yellow 5 Green 6 Blue 7 Purple (Violet if your colour vision is very good) 8 Grey 9 White Each resistor has typically, three colour bands to indicate its value. The first two bands are the numbers and the third band is the number of noughts:  Green: 5 Blue: 6 Red: 2 noughts Value: 5,600 ohms or 5.6K  Yellow: 4 Purple: 7 Green: 5 noughts Value: 4,700,000 ohms or 4.7M or 4M7 The colour bands are read from left to right and the first band is close to one end of the body of the resistor. There is often a fourth band which indicates the manufacturing tolerance: you can ignore that band. Examples: Red, Red, Red: 2 2 00 ohms or 2K2 Yellow, Purple, Orange: 4 7 000 ohms or 47K Black, Brown, Brown: 1 0 0 ohms or 100R Orange, Orange, Orange: 3 3 000 ohms or 33K Brown, Green, Red: 1 5 00 ohms or 1K5 Brown, Green, Black: 1 5 no noughts, or 15 ohms Blue, Grey, Orange: 6 8 000 ohms or 68K Brown, Green, Green: 1 5 00000 ohms or 1,500,000 ohms or 1M5 Yellow, Purple, Brown: 4 7 0 ohms As there are only 12 standard resistor values per decade, there are only 12 sets of the first two colour bands: 10: Brown/Black 12: Brown/Red 15: Brown/Green 18: Brown/Grey 22: Red/Red 27: Red/Purple 33: Orange/Orange 39: Orange/White 47: Yellow/Purple 56: Green/Blue 68: Blue/Grey 82: Grey/Red   The details above give you all the basic information on resistor colour codes but there are a few additional refinements. There is an extra colour band further down the body of the resistor as shown here:  This extra band is used to indicate the manufacturing tolerance of the construction of the resistor. Resistor values are never exact and this rarely has any significant effect on their use in circuits. If some circuit needs very accurate resistor values in it, then buy several resistors of the same nominal value and use an ohm-meter to measure that actual value of each particular resistor and if none are perfect, then use two or more resistors to give the exact value wanted. The tolerance band has the following codes: Silver is ± 10% (i.e. a 10K resistor of this type should be between 9K and 11K) Gold ± 5% (i.e. a 10K resistor of this type should be between 9.5K and 10.5K) Red ± 2% (i.e. a 10K resistor of this type should be between 9.8K and 10.2K) Brown ± 1% (i.e. a 10K resistor of this type should be between 9.9K and 10.1K) Green ± 0.5% (i.e. a 10K resistor of this type should be between 9.95K and 10.05K) Blue ± 0.25% (i.e. a 10K resistor of this type should be between 9.975K and 10.025K) Purple ± 0.1% (i.e. a 10K resistor of this type should be between 9.99K and 10.01K) This type of resistor in the 10% and 5% ranges are the most common as they are the cheapest to buy and so tend to be the most popular. Recently, however, two additions to the coding have been introduced in order to allow for very high specification resistors which the average constructor may never come across. Each of these additions involves one additional colour band. The first additional colour band allows an extra digit in the resistor value, and looks like this:  As before, the colour coding is exactly the same, with the fourth colour band specifying the number of zeros after the digits indicated by the colour bands in front of it. So, in the example shown above, the first band being Red indicates a "2". The second colour band being Purple indicates a "7". The third colour band being Green indicates a "5" and the fourth colour band being Red indicates "2 zeros", so putting those together it produces the value of 27,500 ohms, which can also be written as 27.5 K or more briefly as 27K5. Another example of this is:  The fourth colour band coding has also been extended to include two other colours: Gold: meaning "no zeros and divided by 10" and Silver: meaning "no zeros and divided by 100". So, for example, if the resistor had a fourth colour band which was silver, then the value would be:  Finally, for very high-quality applications (typically military applications), there can be a sixth colour band positioned outside the tolerance band, and that final colour band states how much the resistance value can be expected to alter with changes in temperature. This is not something which is likely to be of any interest to you, but the codes for that final colour band are: Brown: 0.01% of the resistor value for each degree Centigrade change in temperature. Red: 0.005% of the resistor value for each degree Centigrade change in temperature. Yellow: 0.0025% of the resistor value for each degree Centigrade change in temperature. Orange: 0.0015% of the resistor value for each degree Centigrade change in temperature. To put this in context, the worst of these represents a change of 1% in the resistor value when moving from the temperature of ice to the temperature of boiling water. Is this something which you really care about? I don't. Leaving the details of identifying individual resistors, we now come to the interesting part: what happens when there are several resistors in a circuit. The important thing is to keep track of the voltages generated within the circuit. These define the currents flowing, the power used and the way in which the circuit will respond to external events. Take this circuit:  What is the voltage at point ‘A’? If you feel like saying “Who cares?” then the answer is “you” if you want to understand how circuits work, because the voltage at point ‘A’ is vital. For the moment, ignore the effect of the voltmeter used to measure the voltage. If R1 has the same resistance as R2, then the voltage at ‘A’ is half the battery voltage, i.e. 4.5 Volts. Half the battery voltage is dropped across R1 and half across R2. It does not matter what the actual resistance of R1 or R2 is, as long as they have exactly the same resistance. The higher the resistance, the less current flows, the longer the battery lasts and the more difficult it is to measure the voltage accurately. There is no need to do any calculations to determine the voltage at point “A” as it is the ratio of the resistor values which determines the voltage. If you really want to, you can calculate the voltage although it is not necessary. The method for doing this will be shown you shortly. For example, if R1 and R2 each have a value of 50 ohms, then the current flowing through them will be 9 volts / 100 ohms = 0.09 Amps (or 90 milliamps). The voltage drop across R1 will be 50 ohms = Volts / 0.09 amps or Volts = 4.5 volts. Exactly the same calculation shows that the voltage across R2 is exactly 4.5 volts as well. However, the point to be stressed here is that it is the ratio of R1 to R2 which controls the voltage at point “A”. If R1 has half as much resistance as R2, then half as much voltage is dropped across it as is dropped across R2, i.e. 3 Volts is dropped across R1, giving point ‘A’ a voltage of 6 Volts and that is what the voltmeter will show. Again, it does not matter what the actual value of R1 is in ohms, so long as R2 has exactly twice the resistance (shown by a higher number on the resistor). If R1 has twice as much resistance as R2, then twice as much voltage is dropped across it as is dropped across R2, i.e. 6 Volts is dropped across R1, giving point ‘A’ a voltage of 3 Volts. Here are some examples with different resistors:  The same division of the supply voltage can be produced by positioning the slider of a variable resistor at different points by rotating the shaft of the device:  This principle applies immediately to the following circuit:  Here we encounter two new components. The first is ‘VR1’ which is a variable resistor. This device is a resistor which has a slider which can be moved from one end of the resistor to the other. In the circuit above, the variable resistor is connected across the 9 Volt battery so the top of the resistor is at 9 Volts and the bottom is at 0 Volts. The voltage on the slider can be adjusted from 0 Volts to 9 Volts by moving it along the resistor. The second new device is ‘TR1’ a transistor. This semiconductor has three connections: a Collector, a Base and an Emitter. If the base is disconnected, the transistor has a very high resistance between the collector and the emitter, much higher than the resistance of resistor ‘R1’. The voltage dividing mechanism just discussed means that the voltage at the collector will therefore, be very near to 9 Volts - caused by the ratio of the transistor’s Collector/Emitter resistance compared to the resistor “R2”. If a small current is fed from the base to the emitter, the resistance between the collector and the emitter drops almost instantly to a very low value, much, much lower than the resistance of resistor ‘R2’. This means that the voltage at the collector will be very close to 0 Volts. The transistor is described as having ‘switched on’. This state can be set by moving the slider of the variable resistor very slowly upwards to reach the switch-on point. This will be at a base/emitter voltage of 0.7 Volts, or so. The transistor can therefore be switched on and off just by rotating the shaft of the variable resistor. If a bulb is used instead of R2, then it will light when the transistor switches on. If a relay or opto-isolator is used, then a second circuit can be operated. If a buzzer is substituted for R2, then an audible warning will be sounded when the transistor switches on. If a opto-resistor is substituted for VR1, then the transistor will switch on when the light level increases or decreases, depending on how the sensor is connected. If a thermistor is used instead of VR1, then the transistor can be switched on by a rise or fall in temperature. Ditto, for sound, windspeed, water speed, vibration level, etc. etc. - more of this later. We need to examine the resistor circuit in more detail:  We need to be able to calculate what current is flowing around the circuit. This can be done using “Ohms Law” which states that “Resistance equals Voltage divided by Current” or, if you prefer: “Ohms = Volts / Amps” which indicates the units of measurement. In the circuit above, if the voltage is 9 Volts and the resistor is 100 ohms, then by using Ohm’s Law we can calculate the current flowing around the circuit as 100 Ohms = 9 Volts / Amps, or Amps = 9 / 100 which equals 0.09 Amps. To avoid decimal places, the unit of 1 milliamp is used. There are 1000 milliamps in 1 Amp. The current just calculated would commonly be expressed as 90 milliamps which is written as 90 mA. In the circuit above, if the voltage is 9 Volts and the resistor is 330 ohms, then by using Ohm’s Law we can calculate the current flowing around the circuit as 330 = 9 / Amps. Multiplying both sides of the equation by “Amps” gives: Amps x 330 ohms = 9 volts. Dividing both sides of the equation by 330 gives: Amps = 9 volts / 330 ohms which works out as 0.027 Amps, written as 27 mA. Using Ohm’s Law we can calculate what resistor to use to give any required current flow. If the voltage is 12 Volts and the required current is 250 mA then as Ohms = Volts / Amps, the resistor needed is given by: Ohms = 12 / 0.25 Amps which equals 48 ohms. The closest standard resistor is 47 ohms (Yellow / Purple / Black). The final thing to do is to check the wattage of the resistor to make sure that the resistor will not burn out when connected in the proposed circuit. The power calculation is given by: Watts = Volts x Amps. In the last example, this gives Watts = 12 x 0.25, which is 3 Watts. This is much larger than most resistors used in circuitry nowadays. Taking the earlier example, Watts = Volts x Amps, so Watts = 9 x 0.027 which gives 0.234 Watts. Again, to avoid decimals, a unit of 1 milliwatt is used, where 1000 milliwatts = 1 Watt. So instead of writing 0.234 Watts, it is common to write it as 234 mW. This method of working out voltages, resistances and wattages applies to any circuit, no matter how awkward they may appear. For example, take the following circuit containing five resistors:  As the current flowing through resistor ‘R1’ has then to pass through resistor ‘R2’, they are said to be ‘in series’ and their resistances are added together when calculating current flows. In the example above, both R1 and R2 are 1K resistors, so together they have a resistance to current flow of 2K (that is, 2,000 ohms). If two, or more, resistors are connected across each other as shown on the right hand side of the diagram above, they are said to be ‘in parallel’ and their resistances combine differently. If you want to work out the equation above, for yourself, then choose a voltage across Rt, use Ohm’s Law to work out the current through Ra and the current through Rb. Add the currents together (as they are both being drawn from the voltage source) and use Ohm’s Law again to work out the value of Rt to confirm that the 1/Rt = 1/Ra + 1/Rb + .... equation is correct. A spreadsheet is included which can do this calculation for you. In the example above, R4 is 1K5 (1,500 ohms) and R5 is 2K2 (2,200 ohms) so their combined resistance is given by 1/Rt = 1/1500 + 1/2200 or Rt = 892 ohms (using a simple calculator). Apply a common-sense check to this result: If they had been two 1500 ohm resistors then the combined value would have been 750 ohms. If they had been two 2200 ohm resistors then the combined value would have been 1100 ohms. Our answer must therefore lie between 750 and 1100 ohms. If you came up with an answer of, say, 1620 ohms, then you know straight off that it is wrong and the arithmetic needs to be done again. So, how about the voltages at points ‘A’ and ‘B’ in the circuit? As R1 and R2 are equal in value, they will have equal voltage drops across them for any given current. So the voltage at point ‘A’ will be half the battery voltage, i.e. 6 Volts. Now, point ‘B’. Resistors R4 and R5 act the same as a single resistor of 892 ohms, so we can just imagine two resistors in series: R3 at 470 ohms and R4+R5 at 892 ohms. Common-sense rough check: as R3 is only about half the resistance of R4+R5, it will have about half as much voltage drop across it as the voltage drop across R4+R5, i.e. about 4 Volts across R3 and about 8 Volts across R4+R5, so the voltage at point ‘B’ should work out at about 8 Volts. We can use Ohm’s Law to calculate the current flowing through point ‘B’: Ohms = Volts / Amps, ( or Amps = Volts / Ohms or Volts = Ohms x Amps) (470 + 892) = 12 / Amps, so Amps = 12 / (470 + 892) Amps = 12 / 1362 or Amps = 0.00881 Amps (8.81 milliamps). Now that we know the current passing through (R4+R5) we can calculate the exact voltage across them: Resistance = Volts / Amps so 892 = Volts / 0.00881 or Volts = 892 x 0.00881 Volts = 7.859 Volts. As our common-sense estimate was 8 Volts, we can accept 7.86 Volts as being the accurate voltage at point ‘B’. The Potentiometer. Just before we leave the subject of resistors and move on to more interesting subjects, we come across the term ‘potentiometer’. This term is often shortened to ‘pot’ and many people use it to describe a variable resistor. I only mention this so that you can understand what they are talking about. A variable resistor is not a potentiometer and really should not be called one. You can skip the rest of this part as it is not at all important, but here is what a potentiometer is: A fancy name for voltage is ‘potential’, so a circuit powered by a 12 Volt battery can be described as having a ‘potential’ of zero volts at the negative side of the battery and a ‘potential’ of plus twelve volts at the positive side of the battery. Ordinary folks like me would just say ‘voltage’ instead of ‘potential’. When a voltmeter is used to measure the voltage at any point in a circuit, it alters the circuit by drawing a small amount of current from the circuit. The voltmeter usually has a high internal resistance and so the current is very small, but even though it is a small current, it does alter the circuit. Consequently, the measurement made is not quite correct. Scientists, in years gone by, overcame the problem with a very neat solution - they measured the voltage without taking any current from the circuit - neat huh? They also did it with a very simple arrangement:  They used a sensitive meter to measure the current. This meter is built so that the needle is in a central position if no current is flowing. With a positive current flowing, the needle deflects to the right. With a negative current flowing, the needle moves to the left. They then connected a variable resistor ‘VR1’ across the same battery which was powering the circuit. The top end of VR1 is at +12 Volts (they called that ‘a potential of +12 Volts’) and the bottom end of VR1 is at zero volts or ‘a potential of zero volts’. By moving the slider of VR1, any voltage or ‘potential’ from zero volts to +12 Volts could be selected. To measure the voltage at point ‘A’ without drawing any current from the circuit, they would connect the meter as shown and adjust the variable resistor until the meter reading was exactly zero. Since the meter reading is zero, the current flowing through it is also zero and the current taken from the circuit is zero. As no current is being taken from the circuit, the measurement is not affecting the circuit in any way - very clever. The voltage on the slider of VR1 exactly matches the voltage at point ‘A’, so with a calibrated scale on the variable resistor, the voltage can be read off. The slick piece of equipment made up from the battery, the variable resistor and the meter was used to measure the ‘potential’ (voltage) at any point and so was called a ‘potentiometer’. So, please humour me by calling a variable resistor a ‘variable resistor’ and not a ‘potentiometer’. As I said before, this is not at all important, and if you want to, you can call a variable resistor a ‘heffalump’ so long as you know how it works. Semiconductors This section deals with discrete semiconductors. A later section deals with ‘Integrated Circuits’ which are large-scale semiconductor devices. The ORP12 Light-dependent resistor. This device has a high resistance in the dark and a low resistance in bright light. It can be placed in a circuit to create a switch which operates with an increase in light level or a decrease in light level:  In this version, the voltage at point ‘A’ controls the circuit. In darkness, the ORP12 has a resistance ten times greater than that of R1 which is 12,000 ohms. Consequently, the voltage at point ‘A’ will be high. As the light level increases, the resistance of the ORP12 falls, dragging the voltage at point ‘A’ downwards. As the variable resistor ‘VR1’ is connected from point ‘A’ to the ground rail (the -ve of the battery), its slider can be moved to select any voltage between 0 Volts and the voltage of ‘A’. A slider point can be chosen to make the transistor switch off in daylight and on at night. To make the circuit trigger when the light level increases, just swap the positions of R1 and the ORP12. The transistor shown is a BC109 although most transistors will work in this circuit. The BC109 is a cheap, silicon, NPN transistor. It can handle 100mA and 30V and can switch on and off more than a million times per second. It has three connections: the Collector, marked ‘c’ in the diagram, the Base, marked ‘b’ in the diagram and the Emitter, marked ‘e’ in the diagram. As mentioned before, it has a very high resistance between the collector and the emitter when no current flows into the base. If a small current is fed into the base, the collector/emitter resistance drops to a very low value. The collector current divided by the base current is called the ‘gain’ of the transistor and is often called ‘hfe’. A transistor such as a BC109 or a BC108 has a gain of about 200, though this varies from actual transistor to actual transistor. A gain of 200 means that a current of 200mA passing through the collector requires a current of 1mA through the base to sustain it. Specific information on the characteristics and connections of semiconductors of all kinds can be obtained free from the excellent website which provides .pdf information files. The BC109 transistor shown above is an NPN type. This is indicated by the arrow of the symbol pointing outwards. You can also tell by the collector pointing to the positive rail. There are similar silicon transistors constructed as PNP devices. These have the arrow in the transistor symbol pointing inwards and their collectors get connected, directly or indirectly, to the negative rail. This family of transistors are the earliest transistor designs and are called ‘bi-polar’ transistors. These silicon transistors are so efficiently constructed that they can be connected directly together to give greatly increased gain. This arrangement is called a ‘Darlington pair’. If each transistor has a gain of 200, then the pair give a gain of 200 x 200 = 40,000. This has the effect that a very, very small current can be used to power a load. The following diagram shows a Darlington pair used in a water-level detector. This type of alarm could be very useful if you are asleep on a boat which starts taking on water.  Here, (when the circuit is switched on), transistor TR1 has so little leakage current that TR2 is starved of base current and is hard off, giving it a high resistance across its collector/emitter junction. This starves the buzzer of voltage and keeps it powered off. The sensor is just two probes fixed in place above the acceptable water level. If the water level rises, the probes get connected via the water. Pure water has a high electrical resistance but this circuit will still work with pure water. The odds are that in a practical situation, the water will not be particularly clean. The resistor R1 is included to limit the base current of TR1 should the sensor probes be short-circuited. Silicon bi-polar transistors have a base/emitter voltage of about 0.7V when fully switched on. The Darlington pair will have about 1.4V between the base of TR1 and the emitter of TR2, so if the sensor probes are short-circuited together, resistor R1 will have 6 - 1.4 = 4.6V across it. Ohms Law gives us the current through it as R = V / A or 47,000 = 4.6 / A or A = 4.6 / 47,000 amps. This works out at 0.098mA which with a transistor gain of 40,000 would allow up to 3.9A through the buzzer. As the buzzer takes only 30mA or so, it limits the current passing through it, and TR2 can be considered to be switched hard on with the whole battery voltage across it. NPN transistors are more common than PNP types but there is almost no practical difference between them. Here is the previous circuit using PNP transistors:  Not a lot of difference. Most of the circuit diagrams shown here use NPN types but not only are these not critical, but there are several ways to design any particular circuit. In general, the semiconductors shown in any circuit are seldom critical. If you can determine the characteristics of any semiconductor shown, any reasonably similar device can generally be substituted, especially if you have a general understanding of how the circuit works. Either of the two previous circuits can operate as a rain detector. A suitable sensor can easily be made from a piece of strip board with alternate strips connected together to form an interlacing grid:  Here, if a raindrop bridges between any two adjacent strips, the circuit will trigger and sound a warning. The transistors in the circuit above are connected with their emitter(s) connected to the ground rail (the lower battery line shown in any circuit is considered to be “ground” unless it is specifically shown elsewhere). This connection method is called ‘common emitter’. The following circuit uses the transistor connected in ‘emitter follower’ mode. This is where the emitter is left to follow the base voltage - it is always 0.7V below it unless the base itself is driven below 0.7V:  This is almost the same as the light-operated circuit shown earlier. In this variation, the transistors are wired so that they work as an ‘emitter-follower’ which follows the voltage at point ‘A’ which rises as the light level drops and the resistance of the ORP12 increases. This causes the voltage across the relay to increase until the relay operates and closes its contacts. A relay is a voltage-operated mechanical switch which will be described in more detail later on. The disadvantage of the above circuit is that as the light level decreases, the current through the relay increases and it may be a significant amount of current for some considerable time. If it was intended to power the unit with a battery then the battery life would be far shorter than it need be. What we would like, is a circuit which switched rapidly from the Off state to the On state even though the triggering input varied only slowly. There are several ways to achieve this, one of them being to modify the circuit to become a ‘Schmitt Trigger’:  Here, an additional transistor (‘TR2’) has changed the circuit operation significantly, with transistor TR3 switching fully on and fully off, rapidly. This results in the current through the relay being very low until the circuit triggers. The circuit operates as follows. When the voltage at the base of TR1 is high enough, TR1 switches on, which causes the resistance between its collector and emitter to be so low that we can treat it as a short circuit (which is a nearly-zero resistance connection). This effectively connects the 10K and 1K8 resistors in series across the battery. The voltage at their connecting point (both the collector and emitter of TR1) will then be about 1.8 Volts. The two 18K resistors are in series across that voltage so the voltage at their junction will be half that; 0.9 Volts. This puts the Base of TR2 at about 0.9 Volts and its emitter at 1.8 Volts. The base of TR2 is therefore not 0.7 Volts above its emitter, so no base/emitter current will flow in TR2, which means that TR2 is switched hard off. This means that the TR2 collector/emitter resistance will be very high. The voltage at the base of TR3 is controlled by the 1K8 resistor, the TR2 collector/emitter resistance (very high) and the 3K9 resistor. This pushes the base voltage of TR3 up to near the full battery voltage and as it is wired as an emitter-follower, its emitter voltage will be about 0.7 Volts below that. This means that the relay will have most of the battery voltage across it and so will switch hard on. Some practical points: The current flowing into the base of TR3 comes via the 3K9 resistor. A 3K9 resistor needs 3.9 Volts across it for every 1 mA which flows through it. If the relay needs 150 mA to operate and TR3 has a gain of 300, then TR3 will need a base current of 0.5 mA to provide 150 mA of current through its collector/emitter junction. If 0.5 mA flows through the 3K9 resistor, there will be a voltage drop across it of some 2 Volts. The TR3 base/emitter voltage will be a further 0.7 Volts, so the voltage across the relay will be about 12.0 - 2.0 - 0.7 = 9.3 Volts, so you need to be sure that the relay will work reliably at 9 Volts. If you used a Darlington pair of transistors, each with a gain of 300, instead of TR3, then their combined base/emitter voltage drop would be 1.4 Volts, but they would only need a base current of 150 mA / (300 x 300) = 1/600 mA. That current would only drop 0.007 Volts across the 3K9 resistor, so the relay would receive 10.6 Volts. So, how do you work out the gain of any particular transistor? The main working tool for electronics is a multimeter. This is a digital or analogue meter which can measure a wide range of things: voltage, current, resistance, ... The more expensive the meter, generally, the greater the number of ranges provided. The more expensive meters offer transistor testing. Personally, I prefer the older, passive multimeters. These are looked down on because they draw current from the circuit to which they are attached, but, because they do, they give reliable readings all the time. The more modern battery-operated digital multimeters will happily give incorrect readings as their battery runs down. I wasted two whole days, testing rechargeable batteries which appeared to be giving impossible performances. Eventually, I discovered that it was a failing multimeter battery which was causing false multimeter readings. For the moment, let us assume that no commercial transistor tester is to hand and we will build our own (or at least, discover how to build our own). The gain of a transistor is defined as the collector/emitter current divided by the base/emitter current. For example, if 1mA is flowing through the collector and 0.01mA is flowing into the base to sustain that collector flow, then the transistor has a gain of 100 times at 1mA. The transistor gain may vary when it is carrying different current loads. For the circuits we have been looking at so far, 1mA is a reasonable current at which to measure the transistor gain. So let’s build a circuit to measure the gain:  With the circuit shown here, the variable resistor is adjusted until a collector current of 1mA is shown on the milliammeter and the gain of the transistor is then read off the scale on the variable resistor knob. The circuit is built into a small box containing the battery and with a socket into which the transistor can be plugged. The question then is, what values should be chosen for the resistor R1 and the variable resistor VR1? Well, we might choose that the minimum gain to be displayed is 10. This would correspond to where the variable resistor slider is taken all the way up to point ‘A’ in the circuit diagram, effectively taking the variable resistor out of the circuit. If the transistor gain is 10 and the collector current is 1mA, then the base current will be 0.1mA. This current has to flow through the resistor R1 and it has a voltage of (9.0 - 0.7) Volts across it as the base/emitter voltage is 0.7 Volts when the transistor is on. Ohms Law gives us Ohms = Volts / Amps, which for the resistor R1 means Ohms = 8.3 / 0.0001 or 83,000 ohms, or 83K. Rule of thumb: 1K provides 1mA if it has 1V across it, so 10K will give 0.1mA if it has 1 Volt across it. With 8.3 Volts across it, it needs to be 8.3 times larger to hold the current down to the required 0.1mA so the resistor should be 83K in size. As 83K is not a standard size, we need to use two or more standard resistors to give that resistance. Nearest standard size below 83K is 82K, so we can used one 82K resistor and one 1K resistor in series to give the required 83K. Suppose that we say that we would like to have 500 as the highest gain shown on our tester, then when VR1 is at its maximum value, it and R1 should provide 1/500 of the collector current of 1mA, i.e. 0.002mA or 0.000002 Amps. From Ohms Law again we get VR1 + R1 = 4,150,000 ohms or 4M15. Unfortunately, the largest value variable resistor available is 2M2 so the circuit as it stands, will not be able to cope. Suppose we were to just use a 2M2 variable resistor for VR1, what transistor gain range could we display? Well Ohms Law ... lets us calculate the base current with 8.3 Volts across (83,000 + 2,200,000) ohms and from that the maximum transistor gain which would be 277.77 (at 1mA). You would buy a ‘linear’ standard carbon track variable resistor so that the change in resistance is steady as the shaft is rotated. The scale which you would make up would be in even steps and it would run from 10 at the minimum setting, to 278 at the highest setting. But that is not what we wanted. We wanted to measure up to 500. But they don’t make variable resistors big enough, so what can we do? Well, if we wanted, we could lower the battery voltage, which in turn would lower the resistor values. As a 9V battery is very convenient for this kind of circuit, lets not go down that route. We could add extra circuitry to drop the 9V battery voltage down to a lower value. The most simple solution is to add an extra resistor and switch to give two ranges. If we switched in an extra 2M2 resistor above VR1 then the circuit would measure transistor gains from 278 to just over 500 and all we would need to do would be to add a second scale for the VR1 pointer knob to move over. We could, provide extra ranges which overlap and which have more convenient scales to mark. The design is up to you.  The design covered above is not the only way to measure the transistor gain. A second way, which accepts that it is not so accurate, picks a set base current and measures the collector current as a guide to the gain. In this simple method, one or more resistor values are chosen to give gain ranges, and the milliammeter used to read the corresponding gain:  Here, resistor R1 might be chosen to give a collector current of 1mA (which is a full-scale deflection on the meter) when the transistor gain is 100. Resistor R2 might be picked to give a full-scale deflection for a gain of 200, R3 for a gain of 400, R4 for a gain of 600, and so on. Generally speaking, it is not essential to know the exact gain but any reasonable approximation to it is sufficient. You are normally selecting a transistor where you need a gain of 180, so it is not important if the transistor you pick has a gain of 210 or 215 - you are only avoiding transistors with gains below 180. How do you work out the values of the resistors R1 to R4? Well, you probably won’t expect this, but you use Ohms Law. Voltage drop is 8.3 Volts and the base current is given by the full-scale deflection’s 1mA divided by the transistor gain for each range, i.e. 1/100 mA for R1, 1/200 mA for R2,... 1/600 mA for R4,... The Diode One component which has been shown but not described is the diode or ‘rectifier’. This is a device which has a very high resistance to current flowing in one direction and a very low resistance to current flowing in the opposite direction. The base/emitter junction of a transistor is effectively a diode and, at a push, can be used as such. A proper diode is cheap to buy and has far greater voltage and current handling capacities than the base/emitter junction of a transistor. Diodes are mainly made from one of two materials: germanium and silicon. Germanium diodes are used with very small alternating currents such as radio signals coming from an aerial. This is because a germanium diode needs only 0.2 Volts or so to carry a current while silicon needs 0.6 to 0.7 Volts (same as a silicon transistor base/emitter junction). Germanium diodes (and transistors) are very sensitive to temperature change and so are normally restricted to low power circuits. One very neat application for a silicon diode is as an ‘un-interruptible power supply’ where mains failure is caught instantly:  In this circuit, the mains voltage drives the Power Supply Unit which generates 12 Volts at point ‘A’. This provides current to the Load. The diode has +12 Volts at ‘A’ and +12 Volts at point ‘B’ so there is no voltage drop across it and it will not carry current in either direction. This means that the battery is effectively isolated when the mains is functioning. If the Power Supply Unit output were to rise above its design level of +12 Volts, then the diode would block it from feeding current into the battery. If the mains fails, the Power Supply Unit (‘PSU’) output will fall to zero. If the battery and diode were not there, the voltage at point ‘A’ would fall to zero, which would power-down the Load and possibly cause serious problems. For example, if the load were your computer, a mains failure could cause you to lose important data. With a battery back-up of this type, you would have time to save your data and shut your computer down before the battery ran out. The circuit operates in a very simple fashion. As soon as the voltage at point ‘A’ drops to 0.7 Volts below the +12 Volts at point ‘B”, the diode starts feeding current from the battery to the Load. This happens in less than a millionth of a second, so the Load does not lose current. It would be worth adding a warning light and/or a buzzer to show that the mains has failed.  LEDs: There is a widely used variation of the diode which is extremely useful, and that is the Light Emitting Diode or ‘LED’. This is a diode which emits light when carrying current. They are available in red, green, blue, yellow or white light versions. Some versions can display more than one colour of light if current is fed through their different electrical connections. LEDs give a low light level at a current of about 8 or 10 mA and a bright light for currents of 20 to 30 mA. If they are being used with a 12 Volt system, then a series resistor of 1K to 330 ohms is necessary. LEDs are robust devices, immune to shock and vibration. They come in various diameters and the larger sizes are very much more visible than the tiny ones. SCRs and Triacs: Another version of the diode is the Silicon Controlled Rectifier or ‘Thyristor’. This device carries no current until its gate receives an input current. This is just like the operation of a transistor but the SCR once switched on, stays on even though the gate signal is removed. It stays on until the current through the SCR is forced to zero, usually by the voltage across it being removed. SCRs are often used with alternating voltages (described below) and this causes the SCR to switch off if the gate input is removed. SCRs only operate on positive voltages so they miss half of the power available from alternating power supplies. A more advanced version of the SCR is the ‘Triac’ which operates in the same way as an SCR but handles both positive and negative voltages. Opto-Isolators: Another very useful variation on the LED is the Opto-Isolator. This device is a fully enclosed LED and light-sensitive transistor. When the LED is powered up, it switches the transistor on. The big advantage of this device is that the LED can be in a low voltage, low power sensing circuit, while the transistor can be in a completely separate, high voltage, high power circuit. The opto-isolator isolates the two circuits completely from each other. It is a very useful, and very popular, low-cost device. Alternating Current: A battery provides a constant voltage. This is called a Direct Current or ‘DC’ source of power. When a circuit is connected to a battery, the positive rail is always positive and the negative rail is always negative. If you connect a battery to a circuit through a double-pole changeover switch as shown here:  When the changeover switch is operated, the battery is effectively turned over or inverted. This circuit is called an ‘inverter’ because it repeatedly inverts the supply voltage. If the switch is operated on a regular, rapid basis, the graph of the output voltage is as shown on the right. This is a ‘square wave’ voltage and is used extensively in electronic equipment. It is called alternating current or ‘AC’ for short. SCRs and Triacs can be used conveniently with supply voltages of this type. Mains voltage is also AC but is rather different:  Mains voltage varies continuously in the form of a sine wave. In Britain, the mains voltage is described as ‘240 Volts AC’ and it cycles up and down 50 times per second, i.e. 50 positive peaks and 50 negative peaks in one second. It would be reasonable to assume that each voltage peak would be 240 Volts but this is not the case. Even though the supply is described as 240 Volts, it peaks at the square root of 2 times greater than that, i.e. 339.4 Volts. The actual supply voltage is not particularly accurate, so any device intended for mains use should be rated to 360 Volts. In America, the supply voltage is 110 Volts AC and it cycles 60 times per second, peaking at plus and minus 155 Volts. Later on, you will see how one or more diodes can be used to convert AC to DC in a unit which is sold as a ‘mains adapter’ intended to allow battery operated equipment be operated from the local mains supply. Coils: If you take a cardboard tube, any size, any length, and wind a length of wire around it, you create a very interesting device. It goes by the name of a ‘coil’ or an ‘inductor’ or a ‘solenoid’.  This is a very interesting device with many uses. It forms the heart of a radio receiver, it used to be the main component of telephone exchanges, and most electric motors use several of them. The reason for this is if a current is passed through the wire, the coil acts in exactly the same way as a bar magnet:  The main difference being that when the current is interrupted, the coil stops acting like a magnet, and that can be very useful indeed. If an iron rod is placed inside the coil and the current switched on, the rod gets pushed to one side. Many doorbells use this mechanism to produce a two-note chime. A ‘relay’ uses this method to close an electrical switch and many circuits use this to switch heavy loads (a thyristor can also be used for this and it has no moving parts). A coil of wire has one of the most peculiar features of almost any electronic component. When the current through it is altered in any way, the coil opposes the change. Remember the circuit for a light-operated switch using a relay?:  You will notice that the relay (which is mainly a coil of wire), has a diode across it. Neither the relay nor the diode were mentioned in any great detail at that time as they were not that relevant to the circuit being described. The diode is connected so that no current flows through it from the battery positive to the ‘ground’ line (the battery negative). On the surface, it looks as if it has no use in this circuit. In fact, it is a very important component which protects transistor TR3 from damage. The relay coil carries current when transistor TR3 is on. The emitter of transistor TR3 is up at about +10 Volts. When TR3 switches off, it does so rapidly, pushing the relay connection from +10 Volts to 0 Volts. The relay coil reacts in a most peculiar way when this happens, and instead of the current through the relay coil just stopping, the voltage on the end of the coil connected to the emitter of TR3 keeps moving downwards. If there is no diode across the relay, the emitter voltage is forced to briefly overshoot the negative line of the circuit and gets dragged down many volts below the battery negative line. The collector of TR3 is wired to +12 Volts, so if the emitter gets dragged down to, say, -30 Volts, TR3 gets 42 Volts placed across it. If the transistor can only handle, say, 30 Volts, then it will be damaged by the 42 Volt peak. The way in which coils operate seems weird. But, knowing what is going to happen at the moment of switch-off, we deal with it by putting a diode across the coil of the relay. At switch-on, and when the relay is powered, the diode has no effect, displaying a very high resistance to current flow. At switch-off, when the relay voltage starts to plummet below the battery line, the diode effectively gets turned over into its conducting mode. When the voltage reaches 0.7 Volts below the battery negative line, the diode starts conducting and pins the voltage to that level until the voltage spike generated by the relay coil has dissipated. The more the coil tries to drag the voltage down, the harder the diode conducts, stifling the downward plunge. This restricts the voltage across transistor TR3 to 0.7 Volts more than the battery voltage and so protects it. Solenoid coils can be very useful. Here is a design for a powerful electric motor patented by the American, Ben Teal, in June 1978 (US patent number 4,093,880). This is a very simple design which you can build for yourself if you want. Ben’s original motor was built from wood and almost any convenient material can be used. This is the top view:  And this is the side view:  Ben has used eight solenoids to imitate the way that a car engine works. There is a crankshaft and connecting rods, as in any car engine. The connecting rods are connected to a slip-ring on the crankshaft and the solenoids are given a pulse of current at the appropriate moment to pull the crankshaft round. The crankshaft receives four pulls on every revolution. In the arrangement shown here, two solenoids pull at the same moment. In the side view above, each layer has four solenoids and you can extend the crankshaft to have as many layers of four solenoids as you wish. The engine power increases with every layer added. Two layers should be quite adequate as it is a powerful motor with just two layers. An interesting point is that as a solenoid pulse is terminated, its pull is briefly changed to a push due to the weird nature of coils. If the timing of the pulses is just right on this motor, that brief push can be used to increase the power of the motor instead of opposing the motor rotation. This feature is also used in the Adams motor described in the ‘Free-Energy’ section of this document. The strength of the magnetic field produced by the solenoid is affected by the number of turns in the coil, the current flowing through the coil and the nature of what is inside the coil ‘former’ (the tube on which the coil is wound). In passing, there are several fancy ways of winding coils which can also have an effect, but here we will only talk about coils where the turns are wound side by side at right angles to the former.

Transformers Transformers are used to alter the voltage of any alternating current power source. If the alteration increases the output voltage, then the transformer is called a ‘step-up’ transformer. If the output voltage is lower than the input voltage then it is called a ‘step-down’ transformer. If the voltages are the same, it is called an ‘isolation’ transformer. A common construction looks like this:  The Coil bobbin sits on the section of the laminations marked ‘A’ above. The coil is wound on its bobbin former, first one winding and then the second winding. The bobbin is then placed on the central part of the ‘E’ shaped laminations and then completely surrounded by the laminations when the crossbar is placed on the top. The mounting strap is used to hold the two sets of laminations together and provide mounting lugs for attaching the transformer to a chassis. There are typically, twenty laminations in each set and every lamination is insulated from the adjoining laminations. If you want to change the voltage of a battery supply, it is possible to build an electronic circuit to generate an alternating voltage and then use a transformer to change that alternating voltage to whatever voltage you want. The most common form of this, is for generating mains voltage from a 12 Volt car battery, so that mains equipment can be run in remote locations, such as boats, caravans, etc. These circuits are called ‘inverters’ and they are very popular pieces of equipment. The voltage in the secondary coil of any transformer is determined by the ratio of the turns in the primary and secondary windings. For example; if there is a 10 Volt alternating voltage available and you have a transformer which has 100 turns in the primary coil and 1000 turns in the secondary coil. If you connect the 10 Volts across the primary, there will be 100 Volts generated across the secondary coil. Instead, if you connect the 10 Volts across the secondary coil, a voltage of 1 Volts will be generated across the primary winding. This is because there is a 10:1 ratio between the two windings. The Law of Conservation of Energy applies to transformers as it does to everything else. The power input to the primary winding will be the same as the power in the secondary winding minus the losses. The losses, in this case, will be a temperature rise of the whole transformer. If the current passed through the transformer is well below its rated capacity, then the losses will be small. The important point is that 10 Volts at 1 Amp into the primary winding will generate 100 Volts in the secondary, but at somewhat less than 0.1 Amps: Power Input is 10 Watts and Power Output is almost 10 Watts. The voltage has been raised to 100 Volts but the potential current draw has been reduced from 1 Amp to 0.1 Amps (100 mA). In practice, the thickness of the wire used in the windings is very important. If the voltage to be placed across the winding is high, then the wire diameter will be small. Coil windings have fairly low resistances but this is not critical in circuits as coils operate in a peculiar way. Coils have AC ‘impedance’ in addition to their DC ‘resistance’. While Direct Current (from a battery, say) can flow quite easily through a coil with low resistance, Alternating Current may have a hard job getting through the coil due to its high ‘impedance’. Sometimes, coils are used to choke off any AC ripple (interference) coming along a DC power cable. When a coil is used for this purpose it is called a ‘choke’. Each coil has its own resonant frequency and at that frequency it is very difficult for AC to get through the coil. Crystal set radios work on that principle:  Here, the aerial picks up every radio station broadcasting in the area. These are all at different frequencies and they all head down the aerial wire, looking for the easiest path to the earth connection. Most of them run through the coil with no problem whatsoever. If the resonant frequency of the coil matches the frequency of one of the radio stations, then that radio signal (and only that signal) finds it very hard to get through the coil and looks for an easier path to earth. The next easiest path is through the diode and the headphones, so the signal goes that way. The diode blocks part of the signal which generates the sound of the radio broadcast in the headphones. This system works very well indeed if there is a good radio signal. A germanium diode is used as the radio signal voltage is very small and a germanium diode operates on 0.2 Volts while a silicon diode needs 0.7 Volts to operate. That difference is significant at these very low voltages. The resonant frequency of the coil depends on the number of turns in the coil. In this design, the coil has a slider which allows the number of turns to be altered and so, different radio stations to be tuned in. Rectification and Power Supplies We now have the question of how do we turn an alternating voltage into a constant ‘direct’ voltage. The crystal radio set operates by chopping off half of the alternating radio signal. If we were to do this to the output from a mains transformer with an output of say, 12 Volts AC, the result is not very satisfactory:  Here, we have the situation shown in the upper diagram. The output consists of isolated pulses at 50 per second. You will notice that there is no output power for half of the time. The negative part of the waveform is blocked by the high resistance of the diode while the positive part of the waveform is allowed through by the low resistance of the ‘forward-biased’ diode. It should be remembered that the diode drops 0.7 Volts when conducting so the output of the half-wave rectified transformer will be 0.7 Volts lower than the transformer’s actual output voltage. If four diodes are used instead of one, they can be arranged as shown in the lower diagram. This arrangement of diodes is called a ‘bridge’. Here the positive part of the waveform flows through the upper blue diode, the load ‘L’ and on through the lower blue diode. The negative part flows through the left hand red diode, the load and then the right hand red diode. This gives a much better output waveform with twice the power available. The output voltage will be 1.4 Volts less than the transformer output voltage as there are two silicon diodes in the supply chain. The output from even the full-wave rectifier is still unsatisfactory as there is a voltage drop to zero volts 100 times per second. Only a few devices operate well with a power supply like that, an incandescent bulb as used in a car can use this output, but then, it could use the original AC supply without any rectification. We need to improve the output by using a reservoir device to supply current during those moments when the voltage drops to zero. The device we need is a Capacitor which used to be called a ‘condenser’. The circuit of a mains unit using a capacitor is shown here:  This produces a much better result as the capacitor stores some of the peak energy and gives it out when the voltage drops. If the load on the unit is light with not very much current taken from it, the output voltage is quite good. However, if the current drain is increased, the output voltage gets dragged down 100 times per second. This voltage variation is called ‘ripple’ and if the unit is supplying an audio system or a radio, the ripple may well be heard as an annoying hum. The larger the capacitor for any given current draw, the smaller the ripple. To improve the situation, it is normal to insert an electronic control circuit to oppose the ripple:  This circuit uses one new component, a new variety of diode called a ‘Zener’ diode. This device has an almost constant voltage drop across it when its current-blocking direction breaks down. The diode is designed to operate in this state to provide a reference voltage. The circuit merely uses a tiny current from the top of the zener diode to drive the Darlington pair emitter-follower transistors used to provide the output current. With this circuit, when the output current is increased, the resistance of the transistor pair automatically reduces to provide more current without varying the output voltage. The 1K resistor is included to give the transistors a completed circuit if no external equipment is connected across the output terminals. The zener diode is chosen to give 1.4 Volts more than the required output voltage as the two transistors drop 1.4 Volts when conducting. You should note that the output transistor is dropping 6 Volts at the full supply current. Watts = Volts x Amps so the power dissipated by the transistor may be quite high. It may well be necessary to mount the transistor on an aluminium plate called a ‘heat sink’ to keep it from overheating. Some power transistors, such as the 2N3055, do not have the case isolated from the active parts of the transistor. It is good practice to use a mica gasket between the transistor and the heat-sink as it conducts then heat without making an electrical connection to the metal heat-sink. A capacitor, being an electrical reservoir, can be used as part of a timer circuit. If the current flow into it is restricted by passing it through a resistor. The length of time between starting the flow on an empty capacitor, and the voltage across the capacitor reaching some chosen level, will be constant for a high-quality capacitor.  As the voltage increase tails off, it becomes more difficult to measure the difference accurately, so if the capacitor is to be used for generating a time interval, it is normal to use the early part of the graph area where the line is fairly straight and rising fast. The Voltage Doubler It is possible to increase the output voltage of a transformer although this does reduce its ability to supply current at that voltage. The way that this is done is to feed the positive cycles into one storage capacitor and the negative cycles into a second reservoir capacitor. This may sound a little complicated, but in reality, it isn't. A circuit for doing this is shown here:  With this circuit, the transformer output is some voltage, say "V" volts of AC current. This output waveform is fed to capacitor "C1" through diode "D1" which lops off the negative part of the cycle. This produces a series of positive half-cycles which charge up capacitor "C1" with a positive voltage of "V". The other half of the output is fed to capacitor "C2" through diode "D2" which cuts off the positive part of the cycle, causing capacitor "C2" to develop a voltage of -V across it. As the two capacitors are 'in series' and not placed across each other, their voltages add up and produce twice the transformer output voltage. A word of warning here. The transformer is producing an AC waveform and these are marked with the average voltage of the waveform, which is usually a sine wave. The peak voltage of a sinewave is 41% greater than this, so if your transformer has an AC output of 10 volts, then the peaks fed to the capacitors will be about 14.1 volts. If there is no current draw from the capacitors (that is, with the load switched off), then each capacitor will charge to this 14.1 volts and the overall output voltage will be 28.2 volts and not the 20 volts which you might expect. You need to understand that as this is only a half-wave supply, there will be considerable ripple on the output voltage if the current draw is high. Using one additional smoothing capacitor and paying attention to the voltage ratings of the capacitors, the 28 volts supply circuit might be like this:  Multivibrators The number of electronic circuits which can be built with basic components such as resistors, capacitors, transistors, coils, etc. is limited only by your imagination and needs. Here is a circuit where two transistors operate as a pair:  This circuit has two stable states and so it is called a “bi” “stable” or “bistable” circuit. It is important to understand the operation of this simple and useful circuit. If press-button switch ‘A’ is pressed, it short-circuits the base/emitter junction of transistor TR1. This prevents any current flowing in the base/emitter junction and so switches TR1 hard off. This makes the voltage at point ‘C’ rise as high as it can. This leaves transistor TR2 powered by R1 and R2 which have 11.3 Volts across them and switches TR2 hard on. This pulls point ‘D’ down to about 0.1 Volts. This happens in less than a millionth of a second. When the press-button switch ‘A’ is released, transistor TR1 does not switch on again because its base current flows through resistor R3 which is connected to point ‘D’ which is far, far below the 0.7 volts needed to make TR1 start conducting. The result is that when press-button ‘A’ is pressed, transistor TR2 switches on and stays on even when press-button ‘A’ is released. This switches transistor TR3 off and starves the Load of current. This is the first ‘stable state’. The same thing happens when press-button ‘B’ is pressed. This forces transistor TR2 into its ‘off’ state, raising point ‘D’ to a high voltage, switching transistor TR3 hard on, powering the Load and holding transistor TR1 hard off. This is the second of the two ‘stable states’. In effect, this circuit ‘remembers’ which press-button was pressed last, so millions of these circuits are used in computers as Random Access Memory (‘RAM’). The voltage at point ‘C’ is the inverse of the voltage at point ‘D’, so if ‘D’ goes high then ‘C’ goes low and if ‘D’ goes low, then ‘C’ goes high. In passing, the output at ‘D’ is often called ‘Q’ and the output at ‘C’ is called ‘Q-bar’ which is shown as the letter Q with a horizontal line drawn above it. This is shown on the next circuit diagram. A minor variation of this circuit allows a load to be energised when the circuit is powered up:  When powered down, the capacitor ‘C1’ in this circuit is fully discharged through resistor ‘R6’. When the 12 Volts supply is connected to the circuit, capacitor C1 does not charge instantly and so holds the base of TR2 down below 0.7 Volts for much longer than it takes for transistor TR1 to switch on (which, in turn, holds TR2 hard off). Mind you, if it is not necessary to have the Load held powered on indefinitely, then an even more simple circuit can do this:  Here, when the switch is closed, both sides of the capacitor C1 are at +12 Volts and this causes the 1K8 resistor to conduct heavily, driving the transistor and powering the load. The capacitor charges rapidly through the transistor and reaches the point at which it can no longer keep the transistor switched on. When the battery is switched off, the 1M resistor discharges the capacitor, ready for the next time the battery is connected. The Monostable Multivibrator. The monostable has one stable state and one unstable state. It can be flipped out of its stable state but it will ‘flop’ back into its stable state. For that reason, it is also known as a ‘flip-flop’ circuit. It is similar to a bistable circuit, but one of the cross-link resistors has been replaced by a capacitor which can pass current like a resistor, but only for a limited amount of time, after which, the capacitor becomes fully charged and the current flow stops, causing the ‘flop’ back to the stable state once more.  In this circuit, the ‘R’ resistor and the ‘C’ capacitor values determine how long the monostable will be in its unstable state. The circuit operates like this: