|

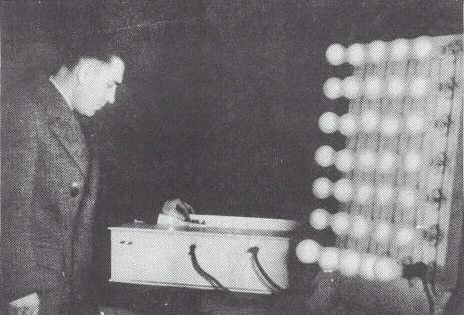

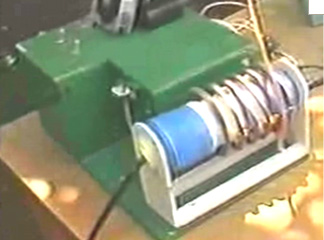

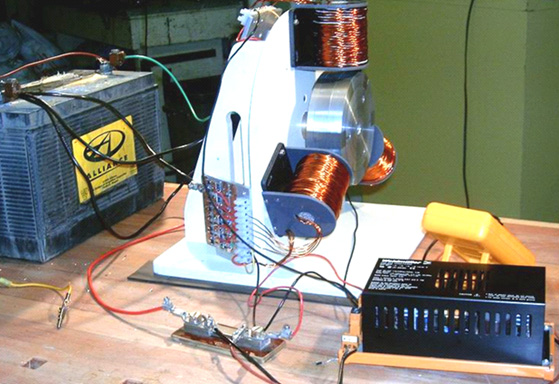

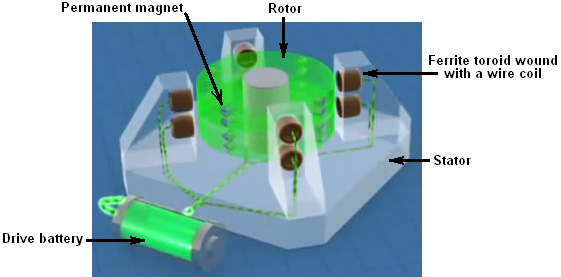

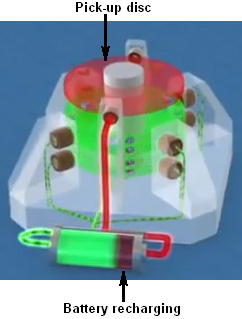

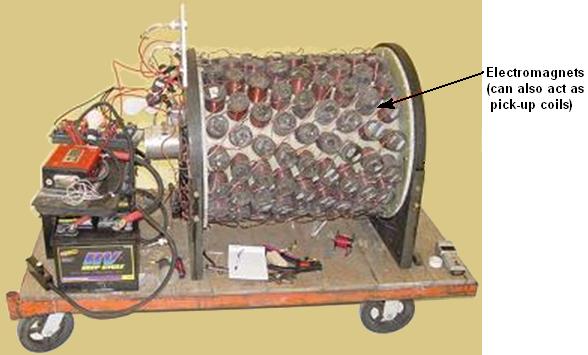

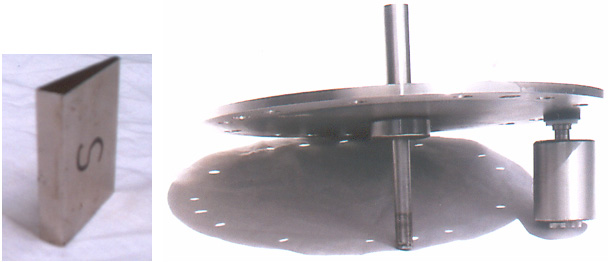

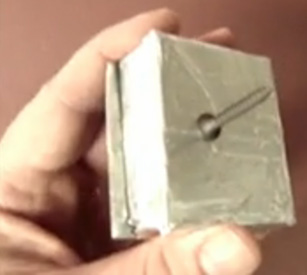

Preface I am just an ordinary person who became interested in “free-energy” as a result of a television programme entitled ‘It Runs on Water’ shown in the 1980s by a UK television company called ‘Channel 4’. This programme has since been put on the internet and at this time can be seen here. From my point of view, the content of this documentary seemed to be rather unsatisfactory as it suggested quite a number of very interesting things but gave no real hard and fast specifics for the viewer to follow up on to investigate the subject further. However, it had the enormous benefit of making me aware that there was such a thing as “free-energy”. My attempts to find out more were not very successful. In 1986 I bought paper copies of several of Stan Meyer’s hydroxy gas patents from the Patent Office but while they were interesting, they did not provide much in the way of additional information. Searching on the internet at that time did not produce much more in the way of practical information. Things have changed dramatically since then and there has been an enormous increase in available information. But, even today, it is relatively difficult to find direct, useful and practical information on free-energy systems and techniques. Much of the information consists of chatty, lightweight articles describing people, events and inventions in vague, broad outline terms which are almost completely lacking in specifics. These articles have the style of saying “There is a new invention called a ‘bus’ which is used to carry passengers from place to place. We saw one the other day, it was painted green and blue and looked most attractive. It is driven by Joe Bloggs who wears an engaging smile and a hand-knitted sweater. Joe says that even his children could drive a bus as it is so easy to do. Joe expects to retire in six months time as he is going to take up gold prospecting.” While I’m sure that an article like that is interesting, the sort of description which I would want would be: “There is a new invention called a ‘bus’ which is used to carry passengers from place to place. We saw one the other day, and were very impressed as it has seats for some forty-five people. It has bodywork made of pressed aluminium, a wheel at each corner of its considerable 40’ x 10’ structure, a five litre diesel engine made by the Bosworth Engineering Company of Newtown, and has power-assisted steering, hydraulic brakes and ……”. There are also many articles, scientific papers and books which, quite frankly, I am not able to understand as the authors think mathematically and express themselves in equations (where they frequently do not define the terms which they use in their equations, making them effectively meaningless). I do not think in mathematical equations, so I do not share in this much higher level of thinking and analysis, though I do have some of these papers on my web site for the benefit of visitors who do have the ability to understand them easily. After a long period of searching and investigating I was beginning to gather enough information to be fairly confident of what was being done, what had already been achieved, and some of the possible background reasons for the effects which were being observed. Early in 2005 I decided that as I had encountered so much difficulty and had to put in so much effort to find out the basics of “free-energy” that it could be helpful to others if I shared what I had found out. So I wrote the first edition of this presentation and created a simple web site to make it available to others. Of course, this body of information is not static – on the contrary, it is very fast-moving. Consequently, this information digest is updated and refined typically once or twice per week. The present form of presentation is the third style of layout which has been used as the volume of material has increased. It should be stressed that this information is what I have discovered as part of my interest in the subject and is mainly a reporting on what is being said by other people. I have not built and proved every device described – to do that would take many lifetimes, so please understand that this is just an attempt to aid your own investigation. While it can be proved that some device works as described, through independent replication and verification, the reverse is not true. If someone were to build a device and fail to get it to work as described, then the most that can honestly be said is that an unsuccessful attempt was made to replicate it. It does not, of course, show that the original device did not operate exactly as described, just that the (possibly inept) attempt at replication, was not successful. In some instances, you will see that I have expressed the opinion that the device is not viable, or, as in the case of the ‘Nitro Cell’ that I do think that it does work, but as many people have tried to build it and failed to get the results described, that it can’t be recommended as an investigation project. I do not suggest that this set of information covers every possible device, nor that my description is by any means the complete and definitive statement of everything to be known on the subject. The old saying applies here: “If you think you know all the answers, then you just haven’t heard all the questions!” So, this material is just an introduction to the subject and not an encyclopedia of every known device. I should like to thank the very large number of people who have most kindly given me their permission to reproduce details of some of their work, providing photographs, checking what I have written, suggesting additions, etc. Also those kind people who have given me permission to reproduce their own works directly on my web sites or in my documents. There seems to be a common thread of concern among many people that shows as a desire to share this information freely rather than to try to make money from selling it, and I thank these people for their generosity. Many people hold “conspiracy theory” views and believe that there is a concerted effort to suppress this information, and more especially, to prevent free-energy devices reaching the market. Personally, I think that the bulk of this opposition is just the normal reaction of vested commercial interests. If you were making a profit of literally millions per hour, would you welcome the introduction of a system which would eventually cut your income to zero? If not, then how much would you be willing to pay someone to make sure that the present system is never changed – a million? A billion? While this opposition is definitely there and people who stand to lose money and/or power through change will continue to oppose this knowledge, and to a much greater extent, the introduction of any commercial free-energy device, this is not something which I feel is immediately relevant to this presentation, and so almost the entire focus of the information is on devices – what they do, how they are made and how they may operate when they draw additional energy from the local environment. Let me stress again, that this set of information is not by any means the final word on the subject, but just an introduction to the subject by a single person who makes no claims to knowing all the answers. Enjoy your research – I hope you are successful in every respect.                  This document contains most of what I have learned about this subject after researching it for a number of years. I am not trying to sell you anything, nor am I trying to convince you of anything. When I started looking into this subject, there was very little useful information and any that was around was buried deep in incomprehensible patents and documents. My purpose here is to make it easier for you to locate and understand some of the relevant material now available. What you believe is up to yourself and none of my business. Let me stress that almost all of the devices discussed in the following pages, are devices which I have not personally built and tested. It would take several lifetimes to do that and it would not be in any way a practical option. Consequently, although I believe everything said is fully accurate and correct, you should treat everything as being “hearsay” or opinion. Some time ago, it was commonly believed that the world was flat and rested on the backs of four elephants and that when earthquakes shook the ground, it was the elephants getting restless. If you want to believe that, you are fully at liberty to do so, however, you can count me out as I don’t believe that. The Wright brothers were told that it was impossible for aeroplanes to fly because they were heavier than air. That was a commonly believed view. The Wright brothers watched birds flying and since, without question, birds are considerably heavier than air, it was clear that the commonly held view was plain wrong. Working from that realisation, they developed aeroplanes which flew perfectly well. The years passed, and the technology started by the Wright brothers and their careful scientific measurements and well-reasoned theory, advanced to become the “science” of aeronautics. This science was used extensively to design and build very successful aircraft and “aeronautics” gained the aura of being a “law”. Unfortunately, somebody applied aeronautic calculations to the flight of bumblebees and discovered that according to aeronautics, bumblebees couldn’t possibly fly as their wings could not generate enough lift to get them off the ground. This was a problem, as it was perfectly possible to watch bees flying in a very competent manner. So, the “laws” of aeronautics said that bees can’t fly, but bees actually do fly. Does that mean that the laws of aeronautics were no use? Certainly not - those “laws” had been used for years and proved their worth by producing excellent aircraft. What it did show was that the “laws” of aeronautics did not yet cover every case and needed to be extended to cover the way that bees fly, which is through lift generated by turbulent airflow. It is very important to realise that what are described as scientific “laws” are just the best working theories at the present time and it is virtually certain that those “laws” will have to be upgraded and extended as further scientific observations are made and further facts discovered. Let’s hope those four elephants don’t get restless before we have a chance to learn a bit more! It should be stressed at this point, that this material is intended to provide you with information and only that. If you should decide, on the basis of what you read here, to build some device or other, you do so solely and entirely at your own risk and on your own responsibility. For example, if you build something in a heavy box and then drop it on your toe, then that is completely your own responsibility (you should learn to be more careful) and nobody other than yourself is in any way liable for your injury, or any loss of income caused while your toe is recovering. Let me amplify that by stating that I do not warrant that any device or system described in this document works as described, or in any other way, nor do I claim that any of the following information is useful in any way or that any device described is useful in any way or for any purpose whatsoever. Also, let me stress that I am not encouraging you to actually construct any device described here, and the fact that very detailed construction details are provided, must not be interpreted as my encouraging you to physically construct any device described in this document. You are welcome to consider this a work of fiction if you choose to do so. I apologise if this presentation seems very elementary, but the intention is to make each description as simple as possible so that everybody can understand it, including people whose native language is not English. If you are not familiar with the basic principles of electronics, then please read the simple step-by-step electronics tutorial in Chapter 12 which is intended to help complete beginners in the subject. At this point in time - the early years of the twenty-first century - we have reached the point where we need to realise that some of the “laws” of science do not cover every case, and while they have been very useful in the past, they do need to be extended to cover some cases which have been left out until now.  For example, suppose a bank robber broke into a bank and stole all of the cash there. How much could he take? Answer: “every coin and every note”. The limit is the sum total of all cash in the building. This is what the “Law” of Conservation of Energy is all about. What it says is very simple – you can’t take out any more than there is there in the beginning. That seems pretty straightforward, doesn’t it? As another example, consider a glass tumbler filled completely with water. Using common sense, tell me, how much water can be poured out of the glass? For the purposes of this illustration, please take it that temperature, pressure, gravity, etc. all remain constant for the duration of the experiment.  The answer is: “the exact volume contained inside the tumbler”. Agreed. This is what present day science says. To be strictly accurate, you will never be able to pour all of the water out as a small amount will remain, wetting the inside of the glass. Another way of putting this is to say that the “efficiency” of the pouring operation is not 100%. This is typical of life in general, where very few, if any, actions are 100% efficient. So, are we agreed with current scientific thinking then – the maximum amount of water which can pour out of the tumbler is the total volume inside the tumbler? This seems simple and straightforward, doesn’t it? Science thinks so, and insists that this is the end of the story, and nothing else is possible. This arrangement is called a “closed system” as the only things being considered are the glass, the water and gravity. Well, unfortunately for current scientific thinking, this is not the only possible situation and “closed systems” are almost unknown in the real world. Mostly, assumptions are made that the effects of anything else around will cancel out and add up to a net zero effect. This is a very convenient theory, but unfortunately it has no basis in reality. Let’s fill our glass with water again and begin to pour it out again, but this time we position it underneath a source of flowing water:  So, now, how much water can be poured out of the tumbler? Answer: “millions of times the volume of the tumbler”. But hang on a moment, haven’t we just said that the absolute limit of water poured from the tumbler has to be the volume inside the tumbler? Yes, that’s exactly what we said, and that is what current science teaching says. The bottom line here is that what current science says does in fact hold true for most of the time, but there are cases where the basic assumption of it being a “closed system” is just not true. One popular misconception is that you can’t get more energy out of a system than you put into it. That is wrong, because the sentence was worded carefully. Let me say it again and this time, emphasise the key words: “you can’t get more energy out of a system than you put into it”. If that were true, then it would be impossible to sail a yacht all the way around the world without burning any fuel, and that has been done many times and none of the driving energy came from the crews. If it were true, then a grain mill driven by a waterwheel would not be able to produce flour as the miller certainly does not push the millstones around himself. If that were true, then nobody would build windmills, or construct solar panels, or tidal power stations. What the statement should say is “more energy can’t be taken out of a system than is put into it” and that is a very different statement. When sailing a yacht, the wind provides the driving force which makes the trip possible. Notice that, it is the environment providing the power and not the sailors. The wind arrived without them having to do anything about it, and a lot less than 100% of the wind energy reaching the yacht actually becomes forward thrust, contributing to the voyage. A good deal of the energy arriving at the yacht ends up stretching the rigging, creating a wake, producing noise, pushing the helmsman, etc. etc. This idea of no more energy coming out of a system than goes into it, is called “The Law of Conservation of Energy” and it is perfectly right, in spite of the fact that it gets people confused. “Free-Energy Devices” or “Zero-Point Energy Devices” are the names applied to systems which appear to produce a higher output power than their input power. There is a strong tendency for people to state that such a system is not possible since it contravenes the Law of Conservation of Energy. It doesn’t. If it did, and any such system was shown to work, then the “Law” would have to be modified to include the newly observed fact. No such change is necessary, it merely depends on your point of view. For example, consider a crystal set radio receiver:  Looking at this in isolation, we appear to have a free-energy system which contradicts the Law of Conservation of Energy. It doesn’t, of course, but if you do not view the whole picture, you see a device which has only passive components and yet which (when the coil is of the correct size) causes the headphones to generate vibrations which reproduce recognisable speech and music. This looks like a system which has no energy input and yet which produces an energy output. Considered in isolation, this would be a serious problem for the Law of Conservation of Energy, but when examined from a common sense point of view, it is no problem at all. The whole picture is:  Power is supplied to a nearby transmitter which generates radio waves which in turn, induce a small voltage in the aerial of the crystal set, which in turn, powers the headphones. The power in the headphones is far, far less than the power taken to drive the transmitter. There is most definitely, no conflict with the Law of Conservation of Energy. However, there is a quantity called the “Coefficient Of Performance” or “COP” for short. This is defined as the amount of power coming out of a system, divided by the amount of power that the operator has to put into that system to make it work. In the example above, while the efficiency of the crystal set radio is well below 100%, the COP is greater than 1. This is because the owner of the crystal radio set does not have to supply any power at all to make it work, and yet it outputs power in the form of sound. As the input power from the user, needed to make it work is zero, and the COP value is calculated by dividing the output power by this zero input power, the COP is actually infinity. Efficiency and COP are two different things. Efficiency can never exceed 100% and almost never gets anywhere near 100% due to the losses suffered by any practical system. As another example, consider an electrical solar panel:  Again, viewed in isolation, this looks like (and actually is) a Free-Energy device if it is set up out of doors in daylight, as current is supplied to the load (radio, battery, fan, pump, or whatever) without the user providing any input power. Again, Power Out with no Power In. Try it in darkness and you find a different result because the whole picture is:  The energy which powers the solar panel comes from the sun.. Only some 17% of the energy reaching the solar panel is converted to electrical current. This is most definitely not a contravention of the Law of Conservation of Energy. This needs to be explained in greater detail. The Law of Conservation of Energy applies to closed systems, and only to closed systems. If there is energy coming in from the environment, then the Law of Conservation of Energy just does not apply, unless you take into account the energy entering the system from outside. People sometimes speak of “over-unity” when talking about the efficiency of a system. From the point of efficiency, there is no such thing as “over-unity” as that would mean that more power was coming out of the system than the amount of power entering the system. Our trusty bank robber mentioned above would have to take out of the bank vault, more money than was actually in it, and that is a physical impossibility. There are always some losses in all practical systems, so the efficiency is always less than 100% of the power entering the system. In other words, the efficiency of any practical system is always under unity. However, it is perfectly possible to have a system which has a greater power output than the power input which we have to put into it to make it work. Take the solar panel mentioned above. It has a terribly low efficiency of about 17%, but, we don’t have to supply it with any power to make it work. Consequently, when it is in sunlight, it’s Coefficient Of Performance (“COP”) is it’s output power (say, 50 watts) divided by the input power needed to make it work (zero watts) which is infinity. So, our humble, well-known solar panel has terrible efficiency of 17% but at the same time it has a COP of infinity. It is now generally accepted that “Dark Matter” and “Dark Energy” form more than 80% of our universe. There is nothing sinister about the adjective “Dark” as in this context, it merely means that we cannot see it. There are many useful things which we utilise, which we can’t see, for example, radio waves, TV signals, magnetism, gravity, x-rays, etc. etc. The fact of the matter is, that we are sitting in a vast field of energy which we can’t see. This is the equivalent of the situation for the crystal set shown above, except that the energy field we are in is very, very much more powerful than the radio waves from a radio transmitter. The problem is, how to tap the energy which is freely available all around us, and get it to do useful work for us. It can definitely be done, but it is not easy to do. Some people think that we will never be able to access this energy. Not very long ago, it was widely believed that nobody could ride a bicycle faster than 15 miles per hour because the wind pressure on the face of the rider would suffocate him. Today, many people cycle much faster than this without suffocating - why? - because the original negative opinion was wrong. Not very long ago, it was thought that metal aircraft would never be able to fly because metal is so much heavier than air. Today, aircraft weighing hundreds of tons fly on a daily basis. Why? - because the original negative opinion was not correct. It is probably worth while, at this point, to explain the basics of Zero-Point Energy. The experts in Quantum Mechanics refer to how the universe operates as “Quantum Foam”. Every cubic centimetre of “empty” space is seething with energy, so much in fact, that if it were converted using Einstein’s famous equation E = mC2 (that is Energy = Mass x a very big number), then it would produce as much matter as can be seen by the most powerful telescope. There is actually nothing “empty” about space. So why can’t we see anything there? Well, you can’t actually see energy. All right then, why can’t you measure the energy there? Well, two reasons actually, firstly, we have never managed to design an instrument which can measure this energy, and secondly, the energy is changing direction incredibly rapidly, billions and billions and billions of times each second. There is so much energy there, that particles of matter just pop into existence and then pop back out again. Half of these particles have a positive charge and half of them have a negative charge, and as they are evenly spread out in three-dimensional space, the overall average voltage is zero. So, if the voltage is zero, what use is that as a source of energy? The answer to that is “none” if you leave it in it’s natural state. However, it is possible to change the random nature of this energy and convert it into a source of unlimited, everlasting power which can be used for all of the things we use mains electricity for today - powering motors, lights, heaters, fans, pumps, ... you name it, the power is there for the taking. So, how do you alter the natural state of the energy in our environment? Actually, quite easily. All that is needed is a positive charge and a negative charge, reasonably near each other. A battery will do the trick, as will a generator, as will an aerial and earth, as will an electrostatic device like a Wimshurst machine. When you generate a Plus and a Minus, the quantum foam is affected. Now, instead of entirely random plus and minus charged particles appearing everywhere, the Plus which you created gets surrounded by a sphere of minus charge particles popping into existence all around it. Also, the Minus which you created, gets surrounded by a spherical-shaped cloud of plus-charge particles popping into existence all around it. The technical term for this situation is “broken symmetry” which is just a fancy way of saying that the charge distribution of the quantum foam is no longer evenly distributed or “symmetrical”. In passing, the fancy technical name for your Plus and Minus near each other, is a “dipole” which is just a techno-babble way of saying “two poles: a plus and a minus” - isn’t jargon wonderful? So, just to get it straight in your mind, when you make a battery, the chemical action inside the battery creates a Plus terminal and a Minus terminal. Those poles actually distort the universe around your battery, and causes vast streams of energy to radiate out in every direction from each pole of the battery. Why doesn’t the battery run down? Because the energy is flowing from the environment and not from the battery. If you were taught basic physics or electrical theory, you will probably have been told that the battery used to power any circuit, supplies a stream of electrons which flows around the circuit. Sorry Chief - it just ain’t like that at all. What really happens is that the battery forms a “dipole” which nudges the local environment into an unbalanced state which pours out energy in every direction, and some of that energy from the environment flows around the circuit attached to the battery. The energy does not come from the battery. Well then, why does the battery run down, if no energy is being drawn from it to power the circuit? Ah, that is the really silly thing that we do. We create a closed-loop circuit (because that’s what we have always done) where the current flows around the circuit, reaches the other battery terminal and immediately destroys the battery’s “dipole”. Everything stops dead in it’s tracks. The environment becomes symmetrical again, the massive amount of readily available free-energy just disappears and you are back to where you started from. But, do not despair, our trusty battery immediately creates the Plus and Minus terminals again and the process starts all over again. This happens so rapidly that we don’t see the breaks in the operation of the circuit and it is the continual recreation of the dipole which causes the battery to run down and lose it’s power. Let me say it again, the battery does not supply the current that powers the circuit, it never has and it never will - the current flows into the circuit from the surrounding environment. What we really need, is a method of pulling off the power flowing in from the environment, without continually destroying the dipole which pushes the environment into supplying the power. That is the tricky bit, but it has been done. If you can do that, then you tap into an unlimited stream of inexhaustible energy, with no need to provide any input energy to keep the flow of energy going. In passing, if you want to check out the details of all of this, Lee and Yang were awarded the Nobel Prize for Physics in 1957 for this theory which was proved by experiment in that same year. This book includes circuits and devices which manage to tap this energy successfully. Today, many people have managed to tap this energy but no commercial device is readily available for home use, though it is quite likely that there will be in the next six months as some are going through mandatory government testing for safety and reliability ahead of production being approved. This situation has been a long time coming. The reason for this is human rather than technical. More than 3,000 Americans have produced devices or ideas for devices but none have reached commercial production due to opposition from influential people who do not want such devices freely available. One technique is to classify a device as “essential to US National Security”. If that is done, then the developer is prevented from speaking to anyone about the device, even if he has a patent. He cannot produce or sell the device even though he invented it. Consequently, you will find many patents for perfectly workable devices if you were to put in the time and effort to locate them, though most of these patents never see the light of day, having been taken by the people issuing these bogus “National Security” classifications. The purpose of this book is to present the facts about some of these devices and more importantly, where possible, explain the background details of why and how systems of that type function. As has been said before, it is not the aim of this book to convince you of anything, just to present you with some of the facts which are not that easy to find, so that you can make up your own mind on the subject. The science taught in schools, colleges and universities at this time, is well out of date and in serious need of being brought up to date. This has not happened for some time now as people who make massive financial profits have made it their business to prevent any significant advance for many years now. However, the internet and free sharing of information through it, is making things very difficult for them. What is it that they don’t want you to know? Well, how about the fact that you don’t have to burn a fuel to get power? Shocking, isn’t it !! Does it sound a bit mad to you? Well, stick around and start doing some thinking. Suppose you were to cover a boat with lots of solar panels which were used to charge a large bank of batteries inside the boat. And if those batteries were used to operate electric motors turning propellers which drive the boat along. If it is sunny weather, how far could you go? As far as the boat can travel while the sun is up and if the battery bank is large, probably most of the night as well. At sun-up on the next day, you can continue your journey. Oceans have been crossed doing this. How much fuel is burned to power the boat? None !! Absolutely none at all. And yet, it is a fixed idea that you have to burn a fuel to get power. Yes, certainly, you can get power from the chemical reaction of burning a fuel - after all, we pour fuel into the tanks of vehicles “to make them go” and we burn oil in the central heating systems of buildings. But the big question is: “Do we have to?” and the answer is “No”. So why do we do it? Because there is no alternative at present. Why is there no alternative at present? Because the people making incredibly large financial profits from selling this fuel, have seen to it that no alternative is available. We have been the suckers in this con trick for decades now, and it is time for us to snap out of it. Let’s have a look at some of the basic facts: Let me start by presenting some of the facts about electrolysis. The electrolysis of water is performed by passing an electric current through the water, causing it to break up into hydrogen gas and oxygen gas. This process was examined in minute detail by Michael Faraday who determined the most energy efficient possible conditions for electrolysis of water. Faraday determined the amount of electric current needed to break the water apart, and his findings are accepted as a scientific standard for the process. I can see no reason for doubting Faraday’s results. We now bump into a problem which scientists are desperate to ignore or deny, as they have the mistaken idea that it contradicts the Law of Conservation of Energy – which, of course, it doesn’t. The problem is an electrolyser design by Bob Boyce of the USA which appears to have an efficiency twelve times greater than Faraday’s maximum possible gas production. This is a terrible heresy in the scientific arena and it gets the average “by the book” scientist very up-tight and flustered. There is no need for this worry. The Law of Conservation of Energy remains intact and Faraday’s results are not challenged. However, an explanation is called for. To start with, let me show the arrangement for a standard electrolyser system:  Here, current is supplied to the electrolyser by the electrical supply. The current flow causes breakdown of the water contained in the electrolyser, resulting in the amount of gas predicted by Faraday (or less if the electrolyser is not well designed and accurately built). Bob Boyce, who is an exceptionally intelligent, perceptive and able man, has developed a system which performs the electrolysis of water using power drawn from the environment. To a quick glance, Bob’s design looks pretty much like a high-grade electrolyser (which it is) but it is a good deal more than that. The practical construction and operational details of Bob’s design are shown in Chapter 10, but for here, let us just consider the operation of his system in very broad outline:  The very important distinction here is that the power flowing into the electrolyser and causing the water to break down and produce the gas output, is coming almost exclusively from the environment and not from the electrical supply. The main function of Bob’s electrical supply is to power the device which draws energy in from the environment. Consequently, if you assume that the current supplied by the electrical supply is the whole of the power driving the electrolyser, then you have a real problem, because, when properly built and finely tuned, Bob’s electrolyser produces up to 1,200% of Faraday’s maximum efficiency production rate. This is an illusion. Yes, the electrical input is exactly as measured. Yes, the gas output is exactly as measured. Yes, the gas output is twelve times the Faraday maximum. But Faraday’s work and the Law of Conservation of Energy are not challenged in any way because the electrical current measured is used primarily to power the interface to the environment and nearly all of the energy used in the electrolysis process flows in from the local environment and is not measured. What we can reasonably deduce is that the energy inflow from the environment is probably about twelve times the amount of power drawn from the electrical supply. At this point in time, we do not have any equipment which can measure this environmental energy. We are in the same position as people were with electrical current five hundred years ago – there was just no equipment around which could be used to make the measurement. That, of course, does not means that electrical current did not exist at that time, just that we had not developed any equipment capable of performing measurement of that current. Today, we know that this environmental energy exists because we can see the effects it causes such as running Bob’s electrolyser, charging batteries, etc. but we can’t measure it directly because it vibrates at right-angles to the direction that electrical current vibrates in. Electrical current is said to vibrate “transversely” while this zero-point energy vibrates “longitudinally”, and so has no effect on instruments which respond transversely such as ammeters, voltmeters, etc. Bob Boyce’s 101-plate electrolyser produces anything up to 100 litres of gas per minute, and that rate of production is able to power internal combustion engines of low capacity. The vehicle alternator is perfectly capable of powering Bob’s system, so the result is a vehicle which appears to run with water as the only fuel. This is not the case, nor is it correct to say that the engine is powered by the gas produced. Yes, it does utilise that gas when running, but the power running the vehicle is coming directly from the environment as an inexhaustible supply. In the same way, a steam engine does not run on water. Yes, it does utilise water in the process, but the power that runs a steam engine comes from burning the coal and not from the water. The Basics of "Free-Energy": This beginner's introduction presumes that you have never heard of free-energy before and would like an outline sketch of what it is all about, so let's begin at the beginning. We tend to have the impression that people who lived a long time ago were not as clever as we are - after all, we have television, computers, mobile phones, games consoles, aeroplanes, …. But, and it is a big "but", the reason why they did not have those things is because science had not advanced far enough for those things to become possible. That did not mean that the people who lived before us were any less clever than we are. For example, could you, personally, come up with an accurate calculation of the circumference of the Earth? This has to be without prior knowledge, no satellites, no astronomical information, no calculators, no computers and no experts to guide you. Eratosthenes did by observing the shadows in two wells some 800 kilometres apart. When was that? More than two thousand years ago. You have probably heard of the geometry of Pythagoras who lived hundreds of years before Eratosthenes, and that geometry is still used in remote areas to lay out the foundations for new buildings. You have probably heard of Archimedes who worked out why things float. He lived more than two thousand years ago. So, how do those people stack up against you and me? Were they stupid people? This is quite an important point because it demonstrates that the body of scientific information enables many things which were not thought possible in earlier times. This effect is not restricted to centuries ago. Take the year 1900. My father was a youngster then, so it is not all that long ago. It would be another three years before Orville and Wilbur Wright made their first 'heavier-than-air' flight, so there no aircraft around in 1900. There were no radio stations and most definitely, no television stations, nor would you have found a telephone inside a house. The only serious forms of information were books and periodicals or teaching establishments which relied on the knowledge of the teachers. There were no cars and the fastest form of transport for the average person was on a galloping horse. Today, it is difficult to grasp what things were like not all that long ago, but come closer in time and look back just fifty years. Then, people researching in scientific fields had to design and build their own instruments before they ever got to experimenting in their chosen fields of knowledge. They were instrument makers, glass-blowers, metal workers, etc. as well as being scientific researchers. Nowadays there are measuring instruments of all kinds for sale ready-made. We have silicon semiconductors which they didn't have, integrated circuits, computers, etc. etc. The important point here is the fact that advances in scientific theory have made possible many things which would have been considered quite ridiculous notions in my father's time. However, we need to stop thinking as if we already know everything there is to know and that nothing which we think of as "impossible !!" could ever happen. Let me try to illustrate this by remarking on just a few things which as recently as the year 1900 would have marked you out as a "lunatic crank", things which we take for granted today because, and only because, we are now familiar with the science behind each of these things.      Today, we know that these things are not just possible, but we take them for granted. We have a mobile phone in our pocket and could easily use it to talk to friends in other countries almost anywhere in the world. It would seem very strange if we could not do that any more. We each have a television and can watch, say, a golf tournament taking place at the other side of the world. We watch in real time, seeing the result of each stroke almost as soon as the golfer does himself. Even suggesting that such a thing was possible might have got you burnt at the stake for witchcraft, not all that long ago, but not having television would seem a very strange situation for us today. If we see a 350 ton metal Boeing 747 aircraft flying past, we would not think it to be strange in any way, let alone think it was "impossible". It is routine, casual travel at 500 mph, a speed which would have been considered to be a fantasy when my father was young. The fact that the aircraft is so heavy, is of no concern to us as we know that it will fly, and does so, routinely, every day of the year. We take for granted, a computer which can do a million things in one second. Today, we have lost the understanding of how big "a million" is, and we know that most people are likely to lose a game of chess if they play against a computer, even a cheap chess computer. What we need to understand is that our present scientific knowledge is far from being comprehensive and there is still a very large amount to be learned, and that things which the average person today would consider "impossible" are quite liable to be casually routine day-to-day devices in just a few years time. This is not because we are stupid but instead it is because our current science still has a long way to go. The objective of this website (http://www.free-energy-info.com/) is to explain some of the things which current science is not teaching at the present time. Ideally, we want a device which will power our homes and cars without the need to burn a fuel of any kind. Before you get the idea that this is some new and wild idea, please remember that windmills have been pumping water, milling grain, lifting heavy loads and generating electricity for a very long time now. Water wheels have been doing similar work for a very long time and both of these devices are fuel-less. The energy which powers windmills and water wheels comes to us via our Sun which heats air and water, causing wind and rain, feeding power to our devices. The energy flows in from our local environment, costs us nothing and will keep on coming whether we make use of it or not. Most of the pictures of wind generators and water wheels which you will see, show devices which would take a large amount of money to set up. The title of this eBook is "The Practical Guide to Free-Energy Devices" and the word "practical" is intended to indicate that most of the things spoken about are things which you, personally, have a reasonable chance of constructing for yourself if you decide to do so. However, while in chapter 14 there are instructions for building your own wind-powered electrical generator from scratch, pumping water uphill without using a fuel and utilising wave power at low cost, these things are subject to the weather. So, because of this, the main subject is the next generation of commercial devices, devices which do not need a fuel in order to function and power our homes and vehicles, devices which operate no matter what the weather is doing. Perhaps I should remark at this point, that the commercial introduction of this new wave of hi-tech devices is being actively opposed by people who will lose a very large stream of revenue when it does eventually happen, as it most certainly will. For example, Shell BP which is a typical oil company, makes about US $3,000,000 profit per hour, every hour of every day of every year, and there are dozens of oil companies. The government makes even more than that out of the operation, with 85% of the sale price of oil in the UK being government tax. No matter what they say, (and they both do like to talk "green" in order to gain popularity), neither would ever for a single moment, consider allowing the introduction of fuel-less power devices, and they have the financial muscle to oppose this new technology at every possible level. For example, some years ago MIT in the USA spent millions proving that on board fuel reformers for vehicles would give us all better fuel economy and cleaner air. They did long-term testing on buses and cars to provide proof. They teamed up with the very large auto-parts supplier Arvin Meritor to put these new devices in production vehicles. Then "One Equity Partners" bought out Arvin Meritor's division that did all the final work to get fuel reformers put into all new vehicles. They created a new company, EMCON Technologies, and that company dropped the fuel reformer from their product line, not because it did not work but because it did work. This is not "conspiracy theory" but a matter of public record. Some years ago, Stanley Meyer, a talented man living in the USA, found a very energy-efficient way of breaking water into a mixture of hydrogen gas and oxygen gas. He pushed on further and found that a vehicle engine could be run on quite a small amount of this "hydroxy" gas if it was mixed with air, water droplets and some of the exhaust gas coming from the engine. He got funding to allow him to start manufacturing retro-fit kits which would allow any car to run on water alone and not use any fossil fuel at all. You can imagine how popular that would have been with the oil companies and the government. Just after getting his funding, Stan was eating a meal at a restaurant when he jumped up, said "I've been poisoned !", rushed out into the car park and died on the spot. If Stan was mistaken, and he died of 'natural causes', then it was remarkably convenient timing for the oil companies and the government, and his retro-fit kit was never manufactured. Even though Stan left behind many patents on the subject, until recently nobody managed to replicate his very low-power electrolyser, then Dave Lawton in Wales achieved the feat and many people have since replicated it by following Dave's instructions. More difficult still is getting an engine to run on no fossil fuel as Stan did, but recently, three men in the UK achieved just that by getting a standard petrol-engined electrical generator to run with water as the only fuel. Interestingly, this is not something which they want to pursue as they have other areas which are of much more interest to them. Consequently, they have no objections to sharing the practical information on what they did and the details are in chapter 10. In very brief outline, they took a standard 5.5 kilowatt generator and delayed the spark timing by some eleven degrees, suppressed the 'waste' spark and fed the engine a mix of air, water droplets and just a small amount of hydroxy gas (measured at three litres per minute). They test-loaded the generator with four kilowatts of electrical equipment to confirm that it worked well under load, and then moved on to larger engines. This is the general style of generator which they used:  And their arrangement for running it without petrol, is shown in outline here, the full details being in chapter 10, including how to make your own high-performance electrolyser:  Conventional science says that it can prove mathematically that it is quite impossible to do this. However, the calculation is massively flawed in that is not based on what is actually happening and worse still, it makes initial assumptions which are just plain wrong. Even if we were not aware of these calculations, the fact that it has been done is quite enough to show that the current engineering theory is out of date and needs to be upgraded. Now, let us consider a device built by John Bedini, a very talented man in the USA. He built a battery-powered motor with a flywheel on the shaft of the motor. This, of course, does not sound like startling stuff, but the crunch is that this motor ran in his workshop for more than three years, keeping it's battery fully charged during that time - now that is startling. The arrangement is like this:  What makes this arrangement different from a standard set-up is that the battery powered motor is not connected directly to the battery but instead is fed with a rapid series of DC pulses. This has two effects. Firstly, that method of driving a motor is very efficient electrically speaking and secondly, when a flywheel is driven with a series of pulses, it picks up additional energy from the local environment. One other unusual feature is the way that the motor shaft spins a disc with permanent magnets mounted on it. These sweep past a matching set of coils attached to a stationary board, forming an ordinary electrical generator and the resulting electrical power which is generated is converted to DC current and fed back to the driving battery, charging it and maintaining its voltage. Standard theory says that a system like this has to be less than 100% efficient because the DC motor is less than 100% efficient (true) and the battery is well below the 100% efficient mark (true). Therefore, the conclusion is that the system cannot possibly work (false). What is not understood by conventional science is that the pulsed flywheel draws in additional energy from the local environment, showing that conventional science theory is inadequate and out of date and needs to be upgraded. An American called Jim Watson built a much larger version of John's system, a version which was twenty feet (6 meters) long. Jim's version not only powered itself, but generated 12 kilowatts of excess electrical power. That extra 12 kilowatts of power must be a considerable embarrassment for conventional science and so they will either ignore it, or deny that it ever existed, in spite of the fact that it was demonstrated at a public seminar. This is what Jim's device looked like:  Working quite independently, an Australian called Chas Campbell, discovered the same effect. He found that if he used an AC motor plugged into the mains, that it was possible to get more work done that the amount it takes to drive the motor.  He used his motor to drive a series of shafts, one of which has a heavy flywheel mounted on it, like this:  The final shaft drives a standard electrical generator and Chas found that he could power electrical equipment from that generator, electrical mains equipment which required greater current that his mains-driven motor did. Chas then took it one stage further and when the system was running at full speed, he switched his mains motor over from the wall socket to his own generator. The system continued to run, powering itself and driving other equipment as well. Conventional science says that this is impossible, which just goes to show that conventional science is out of date and needs to be upgraded to cover system like this where excess energy is flowing in from the local environment. Here is a diagram of how Chas Campbell's system is set up:  Another man has put a video on the web, showing a variation of this same principle. In his case, the flywheel is very light and has simple paddles attached around the rim of the wheel:  He then aims a powerful jet of water from a high-powered water pump, directly at the paddles, driving the wheel round with a rapid series of pulses. The shaft, on which the wheel is mounted, drives a standard electrical generator which lights an ordinary light bulb:  The really interesting part comes next, because he then unplugs the electrical supply to the water pump and switches it over to the generator which the wheel is driving. The result is that the pump powers itself and provides excess electricity which can be used to power other electrical equipment. The arrangement is like this:  Once again, conventional science says that this is impossible, which in turn, demonstrates that conventional science is out of date and needs to be expanded to include these observed facts. Permanent Magnets have continuous power. This should be obvious as one will support its own weight on the vertical face of a refrigerator, for years on end. Conventional science says that permanent magnets can't be used as a source of power. However, the reality is that conventional science just doesn't know the techniques necessary for extracting that power. The New Zealander, Robert Adams produced a motor which appears to be, typically, 800% efficient. This, of course, is impossible according to conventional science. Robert was told that if he shared the information, he would be killed. He decided that at his age, being killed was not a major thing, so he went ahead and published all the details. Motors driven by electrical pulses are always less than 100% efficient. The Adams motor looks like that sort of design but it is not. The motor power comes from the permanent magnets mounted on the rotor and not from an electrical pulse applied to the electromagnets attached to the stator. The magnets are attracted to the metal cores of the stationary electromagnets. This provides the driving power of the motor. The electromagnets are then powered just enough to overcome the backwards drag of the magnets when they have just passed by the cores of the electromagnets. The system works like this: